I need some advice for the build of a small 4.5 x 8. 3,500# trailer to haul the sprayer that I will be building.

The plan is to build it out of 4" 5.4# C channel, since i don't plan to build a top rail for the trailer.

First problem I encountered. The C channel, has a flange of only 1.584" and the spring hangers are 2.25"

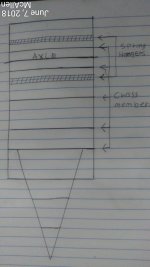

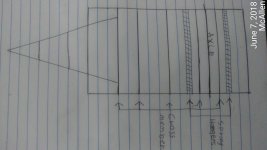

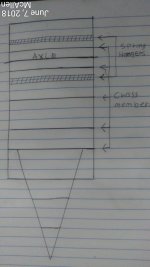

My Idea was to weld a C channel with the flanges facing up across the frame than weld the hangers on the web of that channel.

Here is an ugly drawing of mine

The plan is to build it out of 4" 5.4# C channel, since i don't plan to build a top rail for the trailer.

First problem I encountered. The C channel, has a flange of only 1.584" and the spring hangers are 2.25"

My Idea was to weld a C channel with the flanges facing up across the frame than weld the hangers on the web of that channel.

Here is an ugly drawing of mine