ovrszd

Epic Contributor

- Joined

- May 27, 2006

- Messages

- 33,724

- Location

- Missouri

- Tractor

- Kubota M9540, Ford 3910FWD, Ford 555A, JD2210

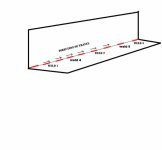

With the information given,,,, I'd repair this from the inside of the bucket. Using the single piece of flat iron I referenced before. This will reinforce that area and prevent a crack later on. Happy welding!!!!