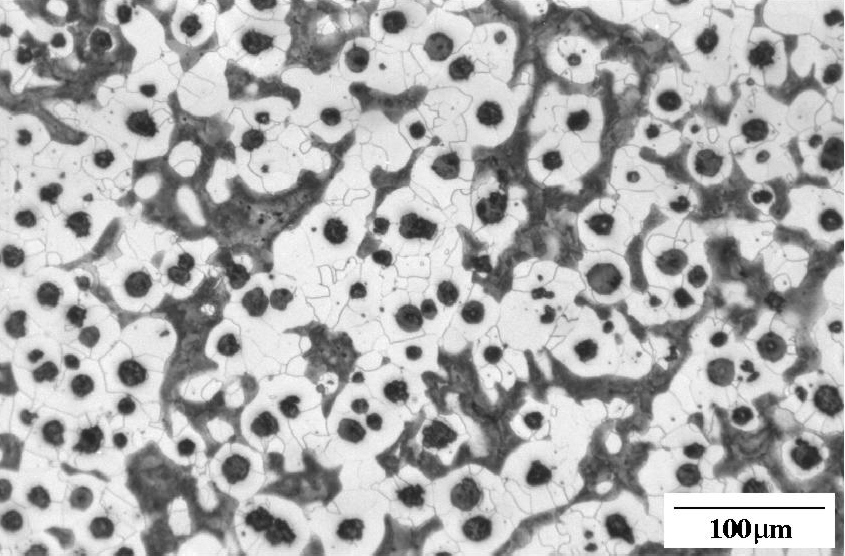

Seeing as it's a gear and you have determined it to be a type of cast iron, I'm guessing it would be ductile or nodular iron, Brinell testing would be a good place to start with if you are trying to determine it's composition through a non-destructive test procedure. If you did have the benefit of doing a destructive material analysis, under a microscope a prepared sample would look something like one of these two examples:

Ductile or Nodular cast iron:

Grey cast Iron by comparison has a more flaky structure and would be more prone to stress fracture, so possibly that is the material that was used and the reason for the parts failure:

"Graphite Nodularity

Cast irons are typically characterized by their nodularity (ductile cast iron) or by their graphite flakes (gray cast iron). Since gray cast irons can eventually fail due to brittle fracture, ductile nodular cast irons are the preferred structure. To produce ductile cast irons, magnesium or cerium are added to the iron melt prior to solidification. Cross-sectional analysis is used to characterize the melt prior to pouring the entire batch."

quote reference: Metallographic Abrasive Cutting

:confused3: All this might be of very little help, but you gotta admit it is pretty interesting!

Best results I have found when attempting to weld a cast iron part was by using Nickel rod, ymmv