Water hammer happens every time a pump starts or stops and every time a valve is opened or closed. Any time water is started moving from a static condition, stopped from a moving condition, or changes direction water hammer happens. Even water just flowing around an elbow or split at a tee causes transient pressure waves that turn into water hammer. A pressure tank or water hammer arrestor cannot stop water hammer. They can only “arrest” it to some degree.

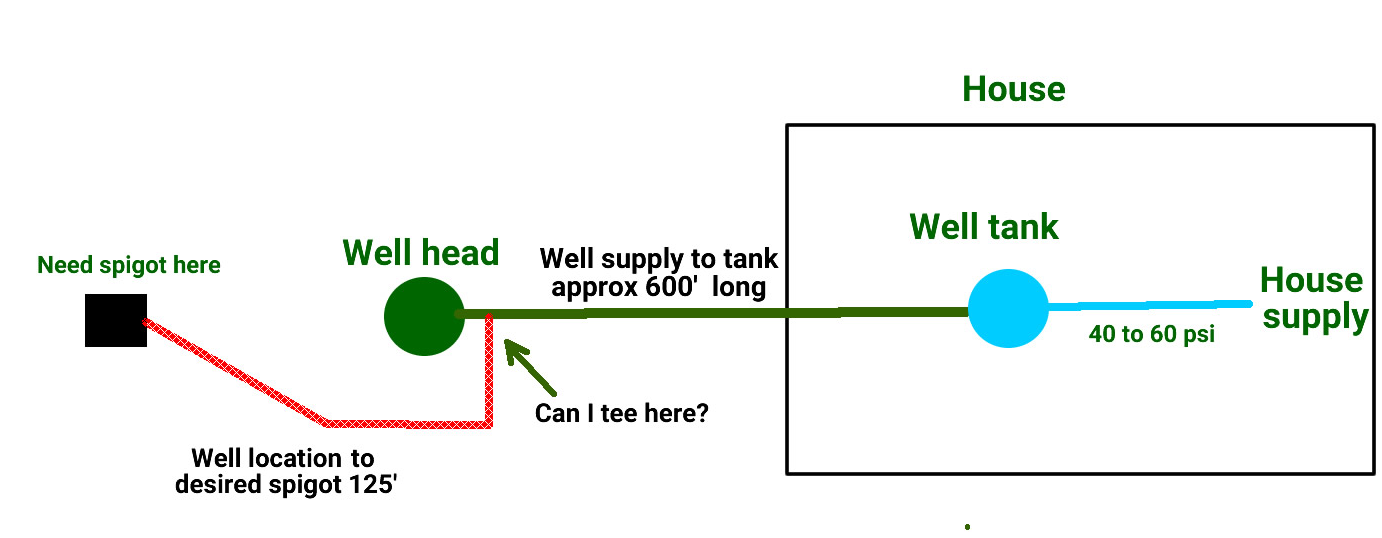

Water hammer or transient pressure waves travel through the pipe from 3,000 to 8,000 feet per second. Faster than a speeding bullet, water hammer travels from where it happens to the other end of the plumbing system far away before you can blink an eye. Closing any hydrant is like dropping a boulder in front of a moving train. In 600’ of 1 ¼” pipe there is 390 pounds of water. All 390 pounds of that water must come to a complete stop when you close the faucet or shower. Friction loss and the sponginess of your pipe are the only things that lessens water hammer. The softer the pipe, the slower the transient pressure wave travels. The slower the transient wave, the lower the damage from water hammer. Softer pipe like Poly only bounces back water hammer waves at 3,000 feet per second while steel pipe bounces the waves back at 8,000 feet per second.

Every time a pump starts it is instantly cramming more weight into that pipe that has 390 pounds of water sitting perfectly still. This is like trying to push a freight train to an instant start of 50 MPH. It would crush the first several freight cars the same way water is trying to split the pipe it is in. Starting the pump causes tremendous pressure pushing against the 390 pounds of water in the pipe blocking the way.

Stopping the pump causes the 390 pounds of water that is flying down the pipe at 5-7 feet per second to stop abruptly and reverse direction, slamming the check valve closed. As this water is coming to a stop from 5-7 fps speed it stretches and turns into a negative pressure. Much like stretching a rubber band, it snaps back. This slams the check valve closed and the resulting pressure wave can be many times more pressure than the pump can even produce.

The softer the pipe, the less damage from water hammer. But the softer the pipe, the less pressure it can take. Water hammer causes damage from the faucet you closed that caused it, all the way to the thrust bearing in the bottom of a submersible motor. Pin holes, splits in the pipe, broken fittings, and any other damage to the plumbing is caused by water hammer unless someone physically steps on the pipe and breaks it.

Slowly opening or closing valves or faucets is the only way to alleviate water hammer on the user side of a water system. Slow closing gate valves are much safer than quarter turn ball valves. Ball valves are my favorite, but the user needs to be trained to close them slowly. Slow closing solenoid or sprinkler valves are a must.

Eliminating water hammer on the pump side of a water system requires starting and stopping the pump against its max pressure. Starting a pump against a closed or almost closed valve lets the 390 pounds of water in the pipe start moving slowly. Closing or almost closing a valve against the pump before shutting the motor off lets the 390 pounds of water in the pipe stop moving slowly. It is also important that the valve opens up as fast as needed to keep negative pressures from being created in the line when someone uses water faster than it is coming from the pump.

This is probably more than most people want to know about water hammer. Lol! But just because your pipe has survived the abuse for 25 years doesn’t mean you don’t have water hammer. And just because your pump survived 25 years cycling on and off over and over doesn’t mean it wouldn’t have lasted twice as long if it had not been cycling. Pumps are designed to last 7 years on average. For every pump that has lasted 25 years there are a couple more that barely made it through the 1 year warranty period before they were cycled to death. For every person who has never experienced water hammer there are a couple more that can’t sleep from the pipes banging in the walls.

A Cycle Stop Valve stops the pump from being cycled on/off to death. A Cycle Stop Valve also starts and stops the pump at only 1 GPM, which eliminates water hammer. Water systems can be so complex that even most engineers are confused. Nearly all the complex issues can be resolved by using a simple Cycle Stop Valve. And before you ask why doesn’t every pump installer use them remember, nearly all issues in a water system are resolved by using a Cycle Stop Valve. That should answer your question.