G'day dbots.

Interesting saga lots of Different Ideas the end result was ,You got the retaining collar of ! Now the bearing!!.

The easiest way to remove the collar IS ,drill a pilot hole into the collar ,Parrallel with the axle you can not go to deep, Increase the size of the hole till you can go no farther ,you will find that if the pilot hole was to close to the axle as you increase the size of drill and it contacts the axle you will find ,the axle being hardened will deflect the drill, this done a good chisel and a copper hammer ,a good hit on the weakest part of the collar and the retaining ring WILL FALL OF.

Keeping the old bearing clean should not be an issue as you WILL BE REPLACING IT with the NEW SEALS !!

To Remove the axle hub assembly make or have made a steel flange using the axle Trumpet housing flange AND the bearing housing for measurements, the flange should be 25 to 30 mm thick and say four hundred MM diameter ,slide it over the bearing housing and use the original hardware to secure the FLANGE to the housing, put the complete thing axle ,hub etc into a press and gently push the axle through the bearing housing, put a block of wood on the floor below the axle or have a willing helper hold onto the axle to avoid damaging it on the way out, i use this method daily and I have never had an axle that would not cooperate .

By using a Puller OR a hollow hydraulic ram YOU WILL BEND the bearing housing hub ,I have had more than one come into my shop asking the question, can you succesfully STRAIGHTEN cast iron???????

NO.

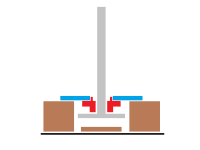

Assemble so:

When everything is cleaned up paying particular attention to the bore of the hub where the bearing fits making sure there is no burrs or areas that will stop the bearing going on ALL THE WAY.

First the Bearing Cup ,I find it easier if you put it in the freezer overnight or in your case put it outside on the verandah, when you are ready to go gently heat the bearing housing concentrating the heat around the area where the bearing will fit not to hot about 180//230 degrees C just below Blue, using Brake fluid coat the OUTSIDE of the bearing cup and install into the housing and don,t laugh make sure it is the correct way up (thin part up ),all the way in.

Next the seal, coat the OUTSIDE of the seal with Permatex NON HARDENING compound and using a FLAT plate 1/2 inch thick at least and large enough to cover the seal area PRESS THE SEAL in ALL THE WAY be careful not to distort or damage the seal business area, fill the void area behind the seal with a good quality bearing grease this will ensure the seal is kept lubricated.

Next the shaft, again pay particular attention to the areas around the shaft seal AND where the bearing cone will rest use fine wet and dry emery paper to give the surface a nice smooth shine lubricate the shaft sealing area with a little bit of grease, and install the shaft into the housing carefully .put the shaft and housing outside overnight and put the bearing into mums oven for 1 hour at 200 degrees c

Make sure the axle etc is ready to receive the hot bearing ,a little lubricant ,brake fluid on the shaft , have a piece of pipe at the ready to knock the bearing home if required , if all is good the bearing will drop all the way down ,when it is in this position give it a light tap with the pipe just to make sure it has seated properly.

Next The retaining collar, heat it up with "the kids" propane torch nice and gently a nice SOFT heat is what you want ,to much oxygen will crystalize the surface and it will not do the collar any good so gently does it, not sure about the temperature but I heat them up till just before red hot ,till you can just see the red appear ,everything ready and double checked install the collar,use pliers and try not to drop it till it is nearly there,this way it wont get a ding on it, again using the piece of pipe and as it is cooling down gently TAP IT A COUPLE OF TIMES JUST TO MAKE SURE IT IS SNUGGED UP.

LET IT COOL ON IT,S OWN do not use water.

Install the assembly:

The axle bearings being tapered rollers need to be preloaded that is the bearings require that there is a constant compressive force applied ,this ensures that ,one the axle assemblies run true and that the machine will carry the weight of a load tthe fact that the two axles contact each other allows you to adjust the preload by adding removing shims behind the hub gasket ,you may have found the remains of the shims when you removed the axle assembly ,

If there were no shims The best way is to buy say six bearing housing to trumpet housing gaskets OR if you can get them an assortment of shims when you buy the new bearings and seals.

Assemble the axle and temporarily install say three gaskets that is install the one new gasket PLUS two or three extra tighten the flange bolts to spec and try to push the axle hub in and out you are trying to establish End float within the axle assembly,when you have end float ,set up a dial indicator which will accuratly measure the end float example there is say 25 thousandths end float that is with the shaft FULLY IN to FULLY OUT you want to remove between 29 to 32 Thousandths this will give the bearing a preload of between four and eight thousandths of an inch which is the final operating preload.

Just a note , when you have established your preload and you remove the axle assembly to adjust ,COAT BOTH SIDES of every gasket surface then reassemble.

That is the axle seal bearing part done.

I have got to go we have a bush fire in the area got to make sure the bulldozer is good to go and the firefighting unit is full.

Will come back to your brake issue later.

Happy days.

Hutch.

P.S.

Check out the fire on google earth ,Stoneville Mundaring Sawyers valley Western Australia we are in Gidgiegannup Springs.