Gary Fowler

Super Star Member

- Joined

- Jun 23, 2008

- Messages

- 11,998

- Location

- Bismarck Arkansas

- Tractor

- 2009 Kubota RTV 900, 2009 Kubota B26 TLB & 2010 model LS P7010

Re: What size pipe did you use for your rear blade痴 cutting edge?

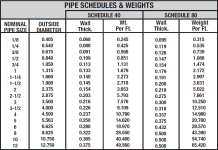

You posted a chart on tubing, not pipe

Edit: I didn't pay close attention to your chart but you are correct in the OD sizing. My original post was concerning the statement that schedule 40 was one OD while Schedule 80 was larger which is not correct. The OD on both schedules of piping is the same regardless of thickness. Tubing OD changes with the schedule thickness so that the ID remains the same. PIPING OD doesn't change regardless of schedule thickness until it reaches 14" nominal pipe size when the ID remains the same just like tubing.

You posted a chart on tubing, not pipe

Edit: I didn't pay close attention to your chart but you are correct in the OD sizing. My original post was concerning the statement that schedule 40 was one OD while Schedule 80 was larger which is not correct. The OD on both schedules of piping is the same regardless of thickness. Tubing OD changes with the schedule thickness so that the ID remains the same. PIPING OD doesn't change regardless of schedule thickness until it reaches 14" nominal pipe size when the ID remains the same just like tubing.