Briar Hill Brittanys

Gold Member

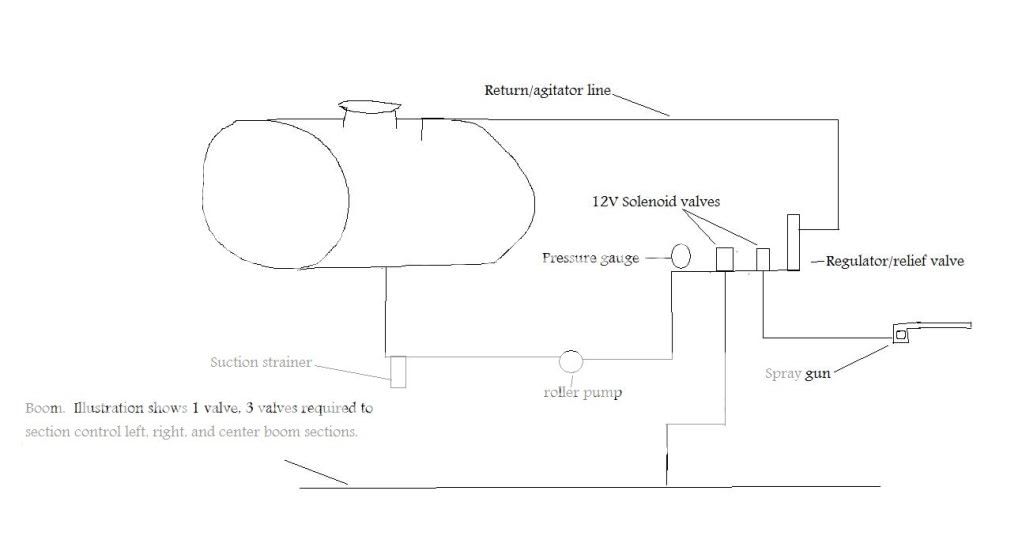

Good lookin' sprayer jdm0125 :thumbsup: . Here's my version, Rev B as it were.  The boom is WAAAY overbuilt. It's a 12'collapsable boom, tips are on 20" spacing. The pump is a 6 roller Silver Series, tank is 35 gallons. Got the tank from Craigslist, the 12V solenoid valves, spray gun, and roller pump from ebay. This is the third year on the pump, when it's put away I fill it with regular anti-freeze and cap the suction and discharge. No problems with locking up as the antifreeze has corrosion inhibitors in it. I just flush a few gallons of fresh water through the system before using. Since the pictures were taken, I've added 2 additional solenoid valves to have the ability to spray left, right, center or any combination by the flick of a switch. This winter I'm planning on a foam marker. I've got a little over $400.00 in it, and way over that in satisfaction during fabrication. The chains hanging on the end of the boom are to set the recommended 20" height for spraying. Mark.

The boom is WAAAY overbuilt. It's a 12'collapsable boom, tips are on 20" spacing. The pump is a 6 roller Silver Series, tank is 35 gallons. Got the tank from Craigslist, the 12V solenoid valves, spray gun, and roller pump from ebay. This is the third year on the pump, when it's put away I fill it with regular anti-freeze and cap the suction and discharge. No problems with locking up as the antifreeze has corrosion inhibitors in it. I just flush a few gallons of fresh water through the system before using. Since the pictures were taken, I've added 2 additional solenoid valves to have the ability to spray left, right, center or any combination by the flick of a switch. This winter I'm planning on a foam marker. I've got a little over $400.00 in it, and way over that in satisfaction during fabrication. The chains hanging on the end of the boom are to set the recommended 20" height for spraying. Mark.

This picture shows the on-board storage for the roller pump.

A close-up of the manifold. When using the boom, I set the RPMs for 44PSI, tractor in 2nd gear. The pressure drops to the recommended 40PSI when the boom is opened. Pressure varies when using the gun, depending on how far I need to spray.

This picture shows the on-board storage for the roller pump.

A close-up of the manifold. When using the boom, I set the RPMs for 44PSI, tractor in 2nd gear. The pressure drops to the recommended 40PSI when the boom is opened. Pressure varies when using the gun, depending on how far I need to spray.