kg7il

Silver Member

My design goals are:

Minimal Material

Minimal Cutting: No Complex Cuts. Straight Cuts Only.

Separate Large Rocks using Grizzly Bar

Provide for interchangeable Screens for sizing.

Easy to disassemble for moving with loader / tractor

Provide for various 'shaker / vibration' methods.

I don't have much more in writing except these pics.

The OVERVIEWS IN BOLD should be sufficient, but detail views included.

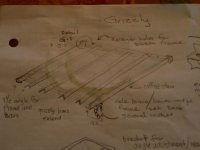

OverView of Grizzly

Grizzly Closeup

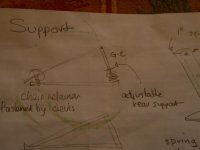

Pivot Bracket for Adjustable Support

Overview of Support and Frame

Support Side View

Adjustable Support with Spring

Minimal Material

Minimal Cutting: No Complex Cuts. Straight Cuts Only.

Separate Large Rocks using Grizzly Bar

Provide for interchangeable Screens for sizing.

Easy to disassemble for moving with loader / tractor

Provide for various 'shaker / vibration' methods.

I don't have much more in writing except these pics.

The OVERVIEWS IN BOLD should be sufficient, but detail views included.

OverView of Grizzly

Grizzly Closeup

Pivot Bracket for Adjustable Support

Overview of Support and Frame

Support Side View

Adjustable Support with Spring