Safetyman9180

New member

- Joined

- Dec 24, 2010

- Messages

- 7

- Tractor

- Yanma YM1401

:newhere:Hi All

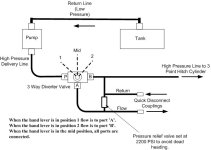

Very new to this site and live in France (but work in the UK) I am in the process of buying a log splitter for my Yanmar 1401 and need to install flow & return hydraulic lines, can anyone confirm or otherwise that its a simple break into the existing pressure and return pipework?

I would hate to do any damage to the pump, additionally looking at previous posts it appears that the 1401 pump delivers around 2-3 gals per minute and the splitter I am buying has a max of 3 gals per minute which I presume would be adequate? Also its an American piece of equipment "Powerhorse 13 Ton Horizontal" Are Japanese gallons american or imperial?

Any wise ones out there your comments would be very much apreciated.

I tried Santa but he didnt know!! Merry Christmas.

Safetyman

Very new to this site and live in France (but work in the UK) I am in the process of buying a log splitter for my Yanmar 1401 and need to install flow & return hydraulic lines, can anyone confirm or otherwise that its a simple break into the existing pressure and return pipework?

I would hate to do any damage to the pump, additionally looking at previous posts it appears that the 1401 pump delivers around 2-3 gals per minute and the splitter I am buying has a max of 3 gals per minute which I presume would be adequate? Also its an American piece of equipment "Powerhorse 13 Ton Horizontal" Are Japanese gallons american or imperial?

Any wise ones out there your comments would be very much apreciated.

I tried Santa but he didnt know!! Merry Christmas.

Safetyman