Guys, need some help. I have decided to undertake building a front end loader. Wife is happy, cause I will spend countless hours in the garage. I have plans from PF Engineering and am I am impressed, and will use his design as a baseline. Certainly within my abilities to construct and the tools I own. I have given up looking for a used loader.

But need some help: The actual mounts for the loader to the frame seem to be very unique as compared to other brands. I have a basic design thought out, but was wondering if any one out there in cyber land has a Yanmar 155D/165D with a loader that could share some photos of their loader mounting?? Not having much luck Goggling to find what I need. Thanks..

I appreciate it.

Bedrock

Yes, I've had a YM165D & loader since it was new. In fact, it was still pretty much new until Nov. 2013 when a flood damaged it. I'll rebuild it someday..... I hope. Although if I could find a good used one I'd sure consider it.

I don't think there is much about that little tractor I don't know, so feel free to ask questions. We can measure my loader when we need to.

It would be nice if you could find an old YFL155 loader or frame.... or at least the bottom framework. But I agree that the original it is such a simple loader that it would be as easy to fabricate one from standard dimensional steel as it would be to adapt a different loader made for some other tractor.

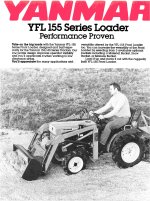

The original loader was named the model YFL155, and it was the same loader for the YM155 and the YM165 tractors - whether 2wd or 4wd. It was simple and rugged. Lightweight and powerful. Many of us could probably design a more sophisticated loader, but I sure couldn't design a better simple loader. It is NOT quick detatchable... once mounted you would have to unbolt it to remove. That is an advantage for simpicity and strength and I never found a reason to remove mine. I've included some pictures with the loader specs. It was an excellent loader for lots of reasons. The most important thing about it was the simple framework and the way the frame connected to the tractor. The frame added strength and rigidity to the whole tractor+loader pair.

You will want to build the bottom framework first. The framework on each side is the same. It is one long piece (orange-red in photos) that is of quarter inch? steel ( I can measure mine for thickness). That frame bolts to the engine in the front (see last photo below) and then extends rearward to bolt to to the heavy rear end casting that carries the rear axle. You MUST use an identical or similar framework because that is what takes the force of the loader and distributes it between the front and rear of the tractor. Otherwise the tractor would break at the bellhousing when you lift a load. The bellhousing on this model is not made to take the bending force of a loader. But with the two bottom frame pieces the loader is strong enough to use with a front as a mini-bulldozer..... or as a "halfback" as one of the photos below shows.

That bottom front-to-rear framework will be your biggest challenge. There are two frames - one for each side of the tractor.

They are identical or nearly so. and are what some call a "handed pair".

For a simple fit, I'd build each side in two pieces. Drill one piece of plate to bolt to the engine and then one piece of plate drilled to bolt up to the rear axle houseing Bolt them on and then weld a piece of plate connecting the two. So the framework is simple, but needs to fit up good. Everything else mounts to it.

The good thing about fabbing the framework is you can take your time. You can continue to use the tractor while you build that framework - and in fact you can leave that framework mounted forever once you make it and bolt it on. It only adds strength to the tractor.

Once you build the bottom framework the rest is much easier. The loader uprights are simple pieces of rectangular steel tubing welded to bolt plates on the bottom and to some U channel welded to top where the loader boom arms pivot on at the other. The loader uprights support the control valve assembly and are also serve to hold the loader's hydraulic oil. Very simple and clever.

There is a tubular supports on each side that runs from the top of the loader upright to the front of the tractor. They are kinda offset for clearance. All this is clear in the photos.

It was a very simple loader. Mostof the pivots are not even bushed, just holes drilled in the stee with pins for pivots through the steel of the loader frame. Instead of expensive cast or machined pieces, this YFL155 loader was constructed by cutting and welding standard dimensional steel plate and tubing. You can buy all the pieces of steel you need at any welding shop.

The cylinders, hoses, valves, pivots, and even the front-mounted pump all all standard universal hydraulic pieces. Nothing special. You can order them online very reasonably from several hydraulic outlets. I do recommend that you buy a bucket somewhere. Used ones are cheap. Check the vacant lot behind your local used tractor shop. But if you prefer to fabricate one we can measure mine.

Good Luck,

rScotty