BukitCase

Elite Member

- Joined

- Feb 17, 2012

- Messages

- 2,749

- Location

- Albany OR

- Tractor

- Case 580B, Long 460, Allis-Chalmers 160

Found out ya can't really mow 3" limbs sticking out of burn piles with a cheapy stamped steel deck  - Bought a Cub RZT50 a few years ago, mowing time went from 2 days to 2 HOURS - the Cub was the only under $3k machine with a Kawasaki, and I'd had good service from the little JD with a smaller Kawasaki.

- Bought a Cub RZT50 a few years ago, mowing time went from 2 days to 2 HOURS - the Cub was the only under $3k machine with a Kawasaki, and I'd had good service from the little JD with a smaller Kawasaki.

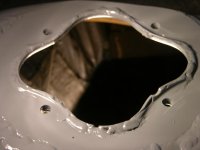

Fast forward to last week - ran over a limb end hidden in the grass, heard scary noises, stopped and found one blade and spindle laying UNDER the deck, spindle housing broken, etc - next few posts show the repair/beef-up. Hopefully it'll work better than the 13 ga. stamped steel deck by itself

Pics, hopefully in order - apparently the pic uploader is STILL broken - chose 10, uploaded, only got the LAST one. Started over and uploaded EACH pic as chosen, so the first one SHOULD be the last one. Oh well...

Pic 2 - broken - Pic 3 - cleaned up - Pic 4 - Worst hole - Pic 5 - 1/8 masonite plaz pattern - Pic 6 - Worst hole closeup - Pic 7 - 3/16" thick reinforcement ring - Pic 8 - fit check - Pic 9 - Clamped @ all 4 bolt holes, tacked in place - Pic 10 - Top site, cracks welded - Pic 1 - Top side, pads leveled, holes cleared.

More to come... Steve

Fast forward to last week - ran over a limb end hidden in the grass, heard scary noises, stopped and found one blade and spindle laying UNDER the deck, spindle housing broken, etc - next few posts show the repair/beef-up. Hopefully it'll work better than the 13 ga. stamped steel deck by itself

Pics, hopefully in order - apparently the pic uploader is STILL broken - chose 10, uploaded, only got the LAST one. Started over and uploaded EACH pic as chosen, so the first one SHOULD be the last one. Oh well...

Pic 2 - broken - Pic 3 - cleaned up - Pic 4 - Worst hole - Pic 5 - 1/8 masonite plaz pattern - Pic 6 - Worst hole closeup - Pic 7 - 3/16" thick reinforcement ring - Pic 8 - fit check - Pic 9 - Clamped @ all 4 bolt holes, tacked in place - Pic 10 - Top site, cracks welded - Pic 1 - Top side, pads leveled, holes cleared.

More to come... Steve

Attachments

-

DSCN1631.JPG127.3 KB · Views: 436

DSCN1631.JPG127.3 KB · Views: 436 -

DSCN1636.JPG128.8 KB · Views: 526

DSCN1636.JPG128.8 KB · Views: 526 -

DSCN1639.JPG126.8 KB · Views: 298

DSCN1639.JPG126.8 KB · Views: 298 -

DSCN1640.JPG121.6 KB · Views: 313

DSCN1640.JPG121.6 KB · Views: 313 -

DSCN1644.JPG127.4 KB · Views: 250

DSCN1644.JPG127.4 KB · Views: 250 -

DSCN1645.JPG110.3 KB · Views: 374

DSCN1645.JPG110.3 KB · Views: 374 -

DSCN1647.JPG117.9 KB · Views: 258

DSCN1647.JPG117.9 KB · Views: 258 -

DSCN1649.JPG123.9 KB · Views: 896

DSCN1649.JPG123.9 KB · Views: 896 -

DSCN1651.JPG115.4 KB · Views: 459

DSCN1651.JPG115.4 KB · Views: 459 -

DSCN1653.JPG107.9 KB · Views: 385

DSCN1653.JPG107.9 KB · Views: 385