I don't see how that would have an effect on stacking pressure....if I'm understanding stacking pressure as simply the vertical load on the joint.

Let me see if I can think through this: I can see how having an attachment point above and below the axle would give the joint strength in terms of lateral loads... loads that would be in the same plane as 'camber'...for lack of a better word. A 'double sheer' arrangement would give strength resisting forces that would affect camber, and thus spread those forces to bearings above and below the axle, not just below.

These types of loads occur (if I'm thinking about this right) primarily when the tractor is turning. I think in particular when making a tight turn with a full load in the bucket, those forces are very high on the inside wheel. The camber (which is not adjustable) on my

L4400, seems extreme to me. The top of the tire sets out wider than the bottom. I'm assuming this provides a tighter turning radius. But, when you have a heavy load in the bucket and make a tight turn, you can see that load's effect on the sidewall of the tire, pushing the bottom of the wheel/tire inward. So it seems to me that in these set ups without the 'double shear' design, a little more neutral camber would put less force on those lower bearings when turning with a load. But hey, I'm no engineer.

Anyway, I may have got this all jumbled up, but it seems to me that for those of us with this type of design, we need to take most care when

turning with a load in the bucket.

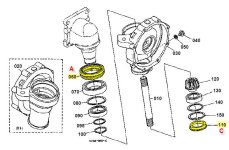

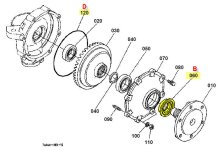

It looks like the MX5100 and the M series tractors have this double sheer set up and none of the L or Grand L's do. But I may be wrong, this is just from looking at the rather poor photos on the Kubota web site.