Well where to begin . . . The RCK60-BX DOES indeed mount on the 3 point hitch of the BX25 WITHOUT ANY ADDITIONAL STEEL. The dealers are clearly not the sharpest tools in the shed . . . Having put this thing on my BX23 I will say however that it was much easier to mount on that unit than on the BX25. The geometry is different between the 2 BX models and it mounts higher off of the ground when on the BX25 than it did when mounted on the BX23. First trick to getting it to mount is buy or borrow a motor cycle jack. You will need it. I used a floor jack and it is not the best because as the GC is jacked up to align the top center link it must be tilted forward to insert the last pin. Mine actually slipped off of my jack and contacted the rear of my BX25 breaking one of my tail light lenses - yep you probably heard me cussing when that happened!

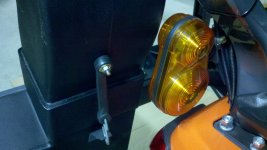

To mount the thing the first time, you will need to rotate your yellow rear mounted turn signals so that the larger round part of the light is down towards the ground and the small one is up. This is exactly the opposite of what Kubota has done when they installed them. The reason for this "adjustment" is because the blower shoot on the right side is so close it will actually hit the light if you don't rotate it 180 degrees. Just losen the nut and turn your light (I turned both so that they match and I honestly think they look better this way). Doing so will allow about 1/4" clearance between the GC shoot & the light once the GC is installed.

Mount the bottom arms on the tractor but DO NOT fasten the turn buckles to the lower arms. Just install the plate with the turnbuckles attched to it (only) to maintain or serve as a spacer between the 2 lower arms. Postion the GC behind the BX25 and align/secure the two lower arms - this is the easy part, very simple but get ready here comes the next and most difficult part of the operation - the top link alignment. GET THAT MOTORCYCLE JACK READY. It would be best to have a second pair of hands the first time you do this to prevent any cursing or broken tail lights. . . . Position the jack just under the RIGHT lower link so that you are jacking up the GC and not the lower link arm. This postion will be about mid-way on the GC from the left &/or right side. Jack slowly and that second pair of hands needs to be careful so that the jack operator doesn't sever any fingers. It will become obvious once you start jacking that the more you jack you will need to tilt the GC forward to align the top center link. IT WILL ALIGN TRUST ME. Once you get that 3rd pin in, the drive shaft is next. Do yourself a big favor and remove your GC's bags. This makes aligning that shaft a breeze if the bags are off, you can just reach right through that area of the GC and hook up the shaft. Install the drive shafts on one another and then the quick coupling on the rear PTO can be secured lastly. Don't forget to attach the turnbuckles to the lower arms and then level things up. REMEMBER, LOWER ARMS, NO TURNBUCKLES, TOP LINK, DRIVE SHAFT, & THEN TIGHTEN YOUR TURNBUCKLES.

I will have to update this one last time. Here is why - when I engaged my rear PTO the GC sheared the PTO shear pin/bolt on the GC drive shaft. I heard it but didn't know what it was at first. There was enough of the bolt still engaged that the GC shafts all continued to rotate. I eventually brought the RPMs up to 3300 and everything did seem like it was working as it should. When I turned off the tractor and walked around to the rear of the BX25, I noticed the shear pin/bolt on the ground and knew immediately what the noise was previously. The next 3 hours were spent trying to remove the rest of the sheared pin/bolt. The drive shaft coupler had turned ever so slightly on the GC shaft which prevented me from being able to drive out the rest of the broken shear pin/bolt. Getting the two shaft pieces realigned so that I could drive out the remaining damaged shear pin/bolt was a royal pain in the butt. Once that was done I called it a night and will need to invest in some new shear pins/bolts at my local dealer - I have gotten to really love my dealer -NOT!!! Plus I need to buy a new right rear tail light lens too - GET THAT MOTORCYCLE JACK, it will save you having to buy a tail light lense and it is much safer than a floor jack. The GC rear PTO drive shaft on the BX25 does have quite an angle to it when mounted. This might be why my shear pin/bolt snapped, I don't know for sure just yet, I'll try it again when I can locate some shear pins/bolts and update this then. The drive shaft angle didn't appear to be so great as to limit or prevent any movement. Hope this helps . . .