jinman

Rest in Peace

- Joined

- Feb 23, 2001

- Messages

- 21,008

- Location

- Texas - Wise County - Sunset

- Tractor

- NHTC45D, NH LB75B, Ford Jubilee

Well, my hydraulic pump is back in my tractor and working quite well. The total charge for the seal kit and replacement was $188. That's not too bad in my book. Of course, I needed to buy some o-ring seals and such, so the total cost of the repair was around $200. That's a whole lot better than the price of a new pump.:thumbsup:

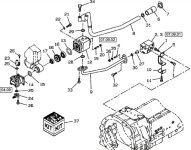

Below, I've included an illustration of the piping. Notice item #9, the high pressure line between the pump and the diverter valve. At the diverter valve end are an o-ring (item 30) and a thimble shaped screen (item 27). The screen was partially clogged with brown fibrous looking trash (2nd image). I cleaned the screen and put in a new o-ring, then used grease as "glue" to hold everthing in place during installation. The 3rd image shows a bad cellphone image looking up at the bottom of the pump with one bolt installed. The last image shows the pipe going into the diverter valve. Note the large suction line above the smaller high pressure line. I don't know if it is just me or what, but the line to the diverter valve has only two small bolts and an o-ring to hold back 2500 psi of hydraulic pressure. It's amazing that it doesn't leak.

When I got all finished and the pump checked out, I reinstalled my loader. I was all excited and then my heart sank when I noticed one of my loader quick connects was leaking. A quick inspection turned up a quick connect o-ring with a chunk missing out of it.:smiley_aafz: So off to my NH dealer I went and bought another o-ring (actually a couple to have a spare). It seems it's always something when you own equipment or a house. These things can nickel and dime you to death. I'll cross my fingers and hope there are no more failures for awhile.

I'll cross my fingers and hope there are no more failures for awhile.

EDIT: I had a picture out of sequence. I added the final picture of the tube to the diverter at the end of the series.

Below, I've included an illustration of the piping. Notice item #9, the high pressure line between the pump and the diverter valve. At the diverter valve end are an o-ring (item 30) and a thimble shaped screen (item 27). The screen was partially clogged with brown fibrous looking trash (2nd image). I cleaned the screen and put in a new o-ring, then used grease as "glue" to hold everthing in place during installation. The 3rd image shows a bad cellphone image looking up at the bottom of the pump with one bolt installed. The last image shows the pipe going into the diverter valve. Note the large suction line above the smaller high pressure line. I don't know if it is just me or what, but the line to the diverter valve has only two small bolts and an o-ring to hold back 2500 psi of hydraulic pressure. It's amazing that it doesn't leak.

When I got all finished and the pump checked out, I reinstalled my loader. I was all excited and then my heart sank when I noticed one of my loader quick connects was leaking. A quick inspection turned up a quick connect o-ring with a chunk missing out of it.:smiley_aafz: So off to my NH dealer I went and bought another o-ring (actually a couple to have a spare). It seems it's always something when you own equipment or a house. These things can nickel and dime you to death.

EDIT: I had a picture out of sequence. I added the final picture of the tube to the diverter at the end of the series.