dragoneggs

Super Star Member

- Joined

- Jun 9, 2013

- Messages

- 14,617

- Location

- Seabeck, Washington

- Tractor

- Kubota BX-25D, Kubota Z122RKW-42

What holds the PAF to the ROPS while the adhesive sets?

I could see using these studs to clamp third function hoses to a loader boom.

Yes boom applications are ideal for CB parts. Large cranes are using them to attach lighting. Anywhere you don't want to upset the integrity of the design. It is almost always the case that a crack will originate at a hole. The other big benefit besides fatigue is corrosion prevention, especially when you bond directly to the paint.

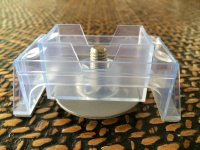

The PAFs have some 3M double back tape on the two 'feet' the old the fixture to the substrate. Here are a a couple of close up pics of the fixture. Note the over centering cam springs that actuate on pressing.