You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Starting a Barn

- Thread starter Sinecure

- Start date

/ Starting a Barn

#41

I579rbd - Thanks for the comments and good question.

The advantage of the hangers is really ease of installation.

I would have loved to do some true joinery (mortise and tenon), but that is hard to do with built-up LVL's and does require some special tools to get it right. Actually, I guess you could do it with a big drill bit and a chisel, but then you have to factor in the time factor. If I was willing to do that, I probably would have opted for a true post and beam barn build from the start. I really wanted to, but that would have been a significant investment of both time and money.

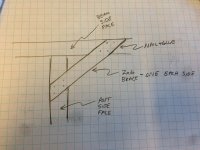

I really don't like the look of the hanger. I know the beam needs some bracing (beam / back down to the post). I am thinking something along the lines of this.

The advantage of the hangers is really ease of installation.

I would have loved to do some true joinery (mortise and tenon), but that is hard to do with built-up LVL's and does require some special tools to get it right. Actually, I guess you could do it with a big drill bit and a chisel, but then you have to factor in the time factor. If I was willing to do that, I probably would have opted for a true post and beam barn build from the start. I really wanted to, but that would have been a significant investment of both time and money.

I really don't like the look of the hanger. I know the beam needs some bracing (beam / back down to the post). I am thinking something along the lines of this.

I know many people will use 3 2x12's with a piece of plywood sandwiched between to make a beam. I thought about this, but opted to go with the LVLs.

My main line of thinking focused around two points:

It is hard to get 3 2x12s that are even (same crown/bow/etc). This would not allow for a true - perfectly straight piece of lumber.

I would have needed to assemble the mocked-up beam on the ground and then install. In all honesty, I would not be able to lift it into place.

With the LVLs, I get a uniform piece of lumber that I am able to lift (one by one) into place. My loader will not reach past the 10 foot height I have the LVLs installed, so I needed to raise them up as high as I can and then manually lift them into the hangers. I was able to do this with the individual LVLs. I am pretty sure I could not have done this with a single beam or built up lumber.

I do pay a price for this however; the LVLs are running me $4.60 a foot.

My main line of thinking focused around two points:

It is hard to get 3 2x12s that are even (same crown/bow/etc). This would not allow for a true - perfectly straight piece of lumber.

I would have needed to assemble the mocked-up beam on the ground and then install. In all honesty, I would not be able to lift it into place.

With the LVLs, I get a uniform piece of lumber that I am able to lift (one by one) into place. My loader will not reach past the 10 foot height I have the LVLs installed, so I needed to raise them up as high as I can and then manually lift them into the hangers. I was able to do this with the individual LVLs. I am pretty sure I could not have done this with a single beam or built up lumber.

I do pay a price for this however; the LVLs are running me $4.60 a foot.

s219

Super Member

- Joined

- Dec 7, 2011

- Messages

- 8,608

- Location

- Virginia USA

- Tractor

- Kubota L3200, Deere X380, Kubota RTV-X

I love working with LVL components -- stays straight and stable a million times better than lumber ever can, which is good for a one-man project where you might not get to button everything down before lumber would start twisting.

Interesting thing I have found with corner braces -- if attached to the inside of the corner, it's very beneficial to be able to notch them in (or even block them in with 2x lumber). Otherwise you are relying on the fastener, usually attached on the diagonal, to do the work, and they can let the brace wiggle/wander. Plus the simple act of snugging-up an un-notched diagonal wants to make it walk (since fastener is on an angle) if you're not careful to snug up each end little by little. So notching or blocking really helps hold it snug.

Inside corner braces can also be attached to post/beam with metal face plates bolted into each, but the labor goes way up.

Another good way to do a corner brace is by face nailing a 2x to each side of the corner, again on a diagonal. You get lots of surface area for the nails to act on, and can put a gob of construction adhesive in there as well. In the end it's very similar to a gusset plate.

Interesting thing I have found with corner braces -- if attached to the inside of the corner, it's very beneficial to be able to notch them in (or even block them in with 2x lumber). Otherwise you are relying on the fastener, usually attached on the diagonal, to do the work, and they can let the brace wiggle/wander. Plus the simple act of snugging-up an un-notched diagonal wants to make it walk (since fastener is on an angle) if you're not careful to snug up each end little by little. So notching or blocking really helps hold it snug.

Inside corner braces can also be attached to post/beam with metal face plates bolted into each, but the labor goes way up.

Another good way to do a corner brace is by face nailing a 2x to each side of the corner, again on a diagonal. You get lots of surface area for the nails to act on, and can put a gob of construction adhesive in there as well. In the end it's very similar to a gusset plate.

S219 - Thanks for the comments. I had planned on rigging up a jig for the router and notching the corner braces into the post and beam, but your comment has got me thinking.

"Corner brace by face nailing a 2x to each side of the corner"

If I am reading your comment correctly, do you mean taking a piece of 2x lumber (2x6 in my case) and essentially mounting a piece on the underside of the beam and then a piece on the vertical post. These would be cut at 45's so when you mounted the corner brace you would essentially have a "triangle" brace assisting to support the beam.

Is my thinking correct? I think I can see it in my head and it may be a better (easier) approach then breaking out the router.

"Corner brace by face nailing a 2x to each side of the corner"

If I am reading your comment correctly, do you mean taking a piece of 2x lumber (2x6 in my case) and essentially mounting a piece on the underside of the beam and then a piece on the vertical post. These would be cut at 45's so when you mounted the corner brace you would essentially have a "triangle" brace assisting to support the beam.

Is my thinking correct? I think I can see it in my head and it may be a better (easier) approach then breaking out the router.

ace10

Silver Member

I would check with manufacturer on extended weather exposure on those LVLs. Especially up on edge like that. We don't know what you're timeline is, but I'm guessing you won't have this weathered in any time soon.

They usually have a coating, but not on the cut ends, and it's not meant to be a permanent weather sealant.

They usually have a coating, but not on the cut ends, and it's not meant to be a permanent weather sealant.

s219

Super Member

- Joined

- Dec 7, 2011

- Messages

- 8,608

- Location

- Virginia USA

- Tractor

- Kubota L3200, Deere X380, Kubota RTV-X

S219 - Thanks for the comments. I had planned on rigging up a jig for the router and notching the corner braces into the post and beam, but your comment has got me thinking.

"Corner brace by face nailing a 2x to each side of the corner"

If I am reading your comment correctly, do you mean taking a piece of 2x lumber (2x6 in my case) and essentially mounting a piece on the underside of the beam and then a piece on the vertical post. These would be cut at 45's so when you mounted the corner brace you would essentially have a "triangle" brace assisting to support the beam.

Is my thinking correct? I think I can see it in my head and it may be a better (easier) approach then breaking out the router.

That's what I would call "blocking" and it will help a lot as you are sandwiching the brace in, and benefiting from nails across the grain from your blocks to your posts (blocks can be oriented with horizontal grain for even stronger results). But I wouldn't put a 45 on the blocks -- I'd leave them with straight cuts and instead put a small chamfer on the diagonal brace (basically blunt off the point of the 45 cut) so that it has a flat "seat" on the block. Then any loads from the brace to the block are going to be normal to the nails. With a 45 on the block, loads would want to peel the block off.

When I said face nailing, I meant take a 2x and nail to each side of the post/beam combo, so the braces are on the outside faces of the corner, like so:

That's also a scenario where nailing across grain with lots of surface area, so they will hold well. This method doesn't look as classy, but it works.

BitChin1

Silver Member

The pic above shows your LVL beam spanning the 16' section (I think).

Which way do you plan to run your joists?

I think the best option would be to have the joists span the 16' direction with the beams spanning the 12' direction to get maximum load capability

Not as good as an engineer but here are a couple of links I use to get direction on these types of questions

Free Beam Sizer - Step 1 of 6

Span Options Calculator for Joists & Rafters

Your might look at Protect-wrap to cover the LVL's from weather as an option.

You definitely need bracing similar to pic in post #43 - many of the post and beam folks cut angles and use large screws for fastening, although notching or side bolting can also work (not sure of the calculations but have a timber framing book that may have the formulas - will check later today)

What are your loft floor loads you expect/want?

Also are you located in a windy area? Any trees that block prevailing wind? these are the types of info you need to determine loads on the building

Which way do you plan to run your joists?

I think the best option would be to have the joists span the 16' direction with the beams spanning the 12' direction to get maximum load capability

Not as good as an engineer but here are a couple of links I use to get direction on these types of questions

Free Beam Sizer - Step 1 of 6

Span Options Calculator for Joists & Rafters

Your might look at Protect-wrap to cover the LVL's from weather as an option.

You definitely need bracing similar to pic in post #43 - many of the post and beam folks cut angles and use large screws for fastening, although notching or side bolting can also work (not sure of the calculations but have a timber framing book that may have the formulas - will check later today)

What are your loft floor loads you expect/want?

Also are you located in a windy area? Any trees that block prevailing wind? these are the types of info you need to determine loads on the building