radioman

Super Member

just an update - one spindle bolt became loose and now its not backing out. i ordered new bellville washers and it should arrrive tues. hopefully they should resolve my issue.

That is what mine did last year. Bolt would not come out. Finally got it out then went on the tap search.just an update - one spindle bolt became loose and now its not backing out. i ordered new bellville washers and it should arrrive tues. hopefully they should resolve my issue.

just an update - one spindle bolt became loose and now its not backing out. i ordered new bellville washers and it should arrrive tues. hopefully they should resolve my issue.

The height of the washer stack is extremely important. Too short and the bolt clamps only the washers leaving the anti spin washer and blade loose. Too long and you have a good clamp but the anti spin washer does not engage the spindle enuf or at all. That can let the spindle turn on the bolt, tightening and wringing it off.

Actually it is the working/compressed stack height that is important. The anti spin washer has a hex shaped hole to engage the hex on the end of the spindle. You need good engagement but cant go more than the thickness of the washer because it will bottom out on the spindle hex and wont flatten the spring washers fully flat to then actually pinch the blade tightly. (Clamping force is way above the point that flattens the "cup" washers.) I have had to tailor my washer stack with a thin extra washer above the Belleville/spring washers - due to wear I guess.In other words, are you saying that if the cup washers are flattened (deformed), the stack will be shorter and therefore the cup washers will not perform their function properly?

Are you also saying that if the spindle/bolt combination slipped on the blade, and then the blade grabbed the bolt for whatever reason, the bolt could experience excessive torque and snap off?

Actually it is the working/compressed stack height that is important. The anti spin washer has a hex shaped hole to engage the hex on the end of the spindle. You need good engagement but cant go more than the thickness of the washer because it will bottom out on the spindle hex and wont flatten the spring washers fully flat to then actually pinch the blade tightly. (Clamping force is way above the point that flattens the "cup" washers.) I have had to tailor my washer stack with a thin extra washer above the Belleville/spring washers - due to wear I guess.

. . . And yes, without the anti spin washer doing its job, blade slips can act to tighten the bolt and wring it off.

Actually it is the working/compressed stack height that is important. The anti spin washer has a hex shaped hole to engage the hex on the end of the spindle. You need good engagement but cant go more than the thickness of the washer because it will bottom out on the spindle hex and wont flatten the spring washers fully flat to then actually pinch the blade tightly. (Clamping force is way above the point that flattens the "cup" washers.) I have had to tailor my washer stack with a thin extra washer above the Belleville/spring washers - due to wear I guess.

. . . And yes, without the anti spin washer doing its job, blade slips can act to tighten the bolt and wring it off.

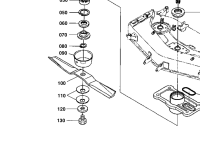

:thumbsup: Thanks for the diagram!Are we talking about the same mower? I am out of town so I cannot check mine, but do have this screen shot from a parts manual I downloaded.

View attachment 604775

Looks like the dust cover is the only thing between the spindle end and the blade surface. On the other side of the blade are the two cup washers, a lock washer, and the bolt goes through the whole works and pulls everything tight against the spindle end.

I see no anti-spin washer. Am I missing the obvious? Would not be the first time.

Looking at this drawing it seems to me the important consideration is the state of the cup washers. Height of the washers would define whether they are satisfactory or need replacement I suppose. But this value is not given...

Bill

The cup/spring/belleville washers spread the clamp force nicely on the blade but they operate totally flat. Older, well used cup washers dont spread the clamp force quite as well, but its the flat thickness of them in their position that is most important. Their spring force is trivial compared to the force applied by the bolt. That force must come directly to bear as a pinch on the blade before the anti spin washer and bolt bottom against the spindle nose.

As I recall, the hex on the ends of the spindles on our bx2660 is somewhere between 1/2"and 3/4" tall.I assume the spindle has a hex shape only towards the end, and the part where the blade fits is circular. If so, if one were to put the anti spin washer on the shaft end, there would be a certain space between the dust cover and the anti spin washer, when the anti spin washer hit the end of the hex portion of the shaft. The question becomes: Is this space greater than the height of the blade plus two compressed cup washers, or not?