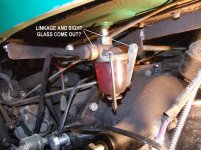

I tried continuing a previous thread entitled "throw out bearing seized???", but did not get much response. So I started this new thread. I am hoping there is someone out there that has more detailed info on how to do this without wasting time on taking apart unnecessary stuff. "Lakespirit" has done this but his notes are more about adjusting the clutch once you get to it. Right now I need to know the best way to actually separate the two halves. There a number of connections above the bell housing just below the dash cover that need to be separated before the front and back can be split . It's basically a matter of knowing which end of a line, or shaft, or bracket, is the easiest to disconnect. Sometimes after struggling for hours getting something apart you realize it would have been a helluva lot easier to have done it from the other side----I'm sure you know what I mean. It's all about being there before, otherwise known as "experience". Any and all suggestions are welcome.

George

George