wedge40

Veteran Member

- Joined

- Oct 8, 2007

- Messages

- 2,197

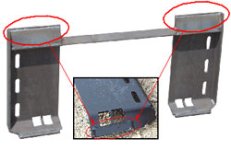

I converted my FEL from a Koyker mount to a standard skid steer mount so I could get a grapple and at some point a set of pallet forks. In doing this I purchased a SS plate off ebay and had it welded to my bucket. I'm having problems getting one side to latch. At a matter of fact I was using too much leverage an broke part of the latch and had to order a new one. Cha-ching.

I put it back to together and I can get one side to latch but the other one (the one I fixed) still wont go.

I've got the spec for SS mount off the net and have been trying to measure the mount hole to make sure it's within spec. But it's a real pain to make an accurate measure.

Here is my plan of attack. Switch the pins from one side to the other, then see if the problem move with the pin or stays on the same side of the mount. If it moves with the pin, then to pin is wrong, if it stays with the mount I'll have to file/grind the hole a little bigger.

I do have another question. Just how far are the pins suppose to go through the bucket mount. Mine are only sticking through about 1/8" and I'm worried that any back drag may bend or break the pin.

Wedge

I put it back to together and I can get one side to latch but the other one (the one I fixed) still wont go.

I've got the spec for SS mount off the net and have been trying to measure the mount hole to make sure it's within spec. But it's a real pain to make an accurate measure.

Here is my plan of attack. Switch the pins from one side to the other, then see if the problem move with the pin or stays on the same side of the mount. If it moves with the pin, then to pin is wrong, if it stays with the mount I'll have to file/grind the hole a little bigger.

I do have another question. Just how far are the pins suppose to go through the bucket mount. Mine are only sticking through about 1/8" and I'm worried that any back drag may bend or break the pin.

Wedge