ridefst

Member

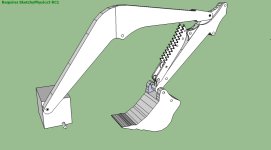

Here's some drawings for a hydraulic thumb I'm working on.

All laser cut 1/2" steel (good to have friends )

)

2" x 16" cylinder

1" pins throughout, also using three pins welded in to space/strengthen the tips. No bracing in the bottom half of the thumb, so the cylinder will fit in the middle when I'm not using it.

Mostly want the thumb to handle that pile of firewood logs in the background.

I've got the hoe to install a bunch of drain tile in the back yard and pasture.

Doesn't seem to be any real good way to design this, unless I'd go for a common pin with the bucket (which seems like too much trouble). Since it's just logs, I'm not too worried about precise control of the tips to the bucket teeth or anything, so I think this'll be okay.

Already got the aux hydraulic lines to the boom, so I should just need to cut/weld this up, and run some short lines.

See anything I'm missing or screwed up?

All laser cut 1/2" steel (good to have friends

2" x 16" cylinder

1" pins throughout, also using three pins welded in to space/strengthen the tips. No bracing in the bottom half of the thumb, so the cylinder will fit in the middle when I'm not using it.

Mostly want the thumb to handle that pile of firewood logs in the background.

I've got the hoe to install a bunch of drain tile in the back yard and pasture.

Doesn't seem to be any real good way to design this, unless I'd go for a common pin with the bucket (which seems like too much trouble). Since it's just logs, I'm not too worried about precise control of the tips to the bucket teeth or anything, so I think this'll be okay.

Already got the aux hydraulic lines to the boom, so I should just need to cut/weld this up, and run some short lines.

See anything I'm missing or screwed up?