County,

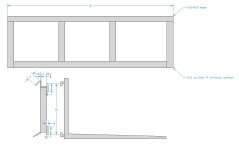

Reg is probably right and there might be a standard spacing, and there are a LOT of different size pallets. My forks float on a solid bar, and while friction keeps them in place I also move them all over the place as needed.

If I was building again and using a rail design I probably wouldn't overthink it. I'd probably just put in as many notches as I wanted to cut. Good luck.

Well, given that he has a pair of (industry standard) forks that have the locking mechanism he might as well use it.

Mine are at 39, 32, 25, 17 and 9 inches - though I think that the 9 inch one may be just for getting the forks on and off.

This is a manageable number, i.e. I can see at a glance which one they are set to without having to count say seventeen notches in from each end.

OTOH, I can see that a very large number of positions would give the ability to - err, I was about to say something about centering the tractor under an off center load, fergettit, just don't mess with loads that are off centered on their pallets, off setting the other way doesn't fix anything (-:

Offsetting to carry pallets across side slopes is a bad idea too.

Sorry, I'm out of rationale to off set.

You can probably find standard pallet specs somewhere - warehousing industries association or somesuch - and figure back from overall width, side rail thickness, fork width, clearance, etc. You will almost certainly get to a list very similar to what I just wrote.