I looked at my machine, and I did not find the same thing as you have, I am guessing that mine is gravity fed . I only found a line running from where the gas tank is ( I couldn't see a actual conection to bottom of tank only top and front but it looks like line comes right through) to small fuel filter,to the carb. there is the line that you have that runs to the valve cover, but on mine it runs from carb to valve cover. Make sense ? I can get a pic tomorrow with my cell phone and try to get it on computer if it helps.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

gas getting in oil pan again, can anyone Help ?

- Thread starter johann

- Start date

- Views: 22791

/ gas getting in oil pan again, can anyone Help ?

#11

jinman

Rest in Peace

- Joined

- Feb 23, 2001

- Messages

- 20,387

- Location

- Texas - Wise County - Sunset

- Tractor

- NHTC45D, NH LB75B, Ford Jubilee

If you see a data plate on the engine with the model number, that would be helpful. The picture I showed is off Kohler's website. If I have the exact model number of your engine, I can try to find more specific info.

What I did find is a description of fuel feed. It said applications with Kohler engines having the fuel tank located above the engine have gravity flow. Those with a fuel tank at or below engine level have a fuel pump. Your pump may be integral to the carb, but I'm pretty darn sure that hose from the valve cover is to provide power to the fuel pump and would be the source of your fuel getting into your engine. I'd check that hose by removing the valve cover end and look for evidence of fuel smell/dripping.

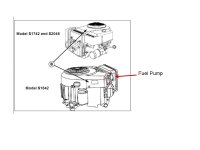

EDIT: I looked at the op manual and it seems your fuel tank is located just in front of the steering column and above the engine. You may not have a fuel pump. However, I found this illustration in the op manual that seems to show a fuel pump on the engine. I think this illustration could be wrong and have the engine models reversed. Perhaps the 1642 engine is at the top.

What I did find is a description of fuel feed. It said applications with Kohler engines having the fuel tank located above the engine have gravity flow. Those with a fuel tank at or below engine level have a fuel pump. Your pump may be integral to the carb, but I'm pretty darn sure that hose from the valve cover is to provide power to the fuel pump and would be the source of your fuel getting into your engine. I'd check that hose by removing the valve cover end and look for evidence of fuel smell/dripping.

EDIT: I looked at the op manual and it seems your fuel tank is located just in front of the steering column and above the engine. You may not have a fuel pump. However, I found this illustration in the op manual that seems to show a fuel pump on the engine. I think this illustration could be wrong and have the engine models reversed. Perhaps the 1642 engine is at the top.

Attachments

Last edited:

jbarker855

Silver Member

If this thing is gravity fed, then it is highly likely that your carb is at fault. I am kind of just guessing at what type of carb you have, but there should be a fuel bowl on bottom of carb attached by a single bolt. Remove this to take bowl off. Remove float. Give the float a shake. If you hear fuel sloshing around in the float, then that is your problem.

Your float could also be misadjusted. Most brass floats have a tang on them that can be adjusted to change fuel level in float bowl.

Could also be a faulty seat for needle. Many of these carbs have a rubber/neoprene ring that the needle seats against. These can get hard/dry and don't seal as well, leading to intermittent flooding. Pull that thing apart, take some pictures, and we'll walk you through it.

-Jay

Your float could also be misadjusted. Most brass floats have a tang on them that can be adjusted to change fuel level in float bowl.

Could also be a faulty seat for needle. Many of these carbs have a rubber/neoprene ring that the needle seats against. These can get hard/dry and don't seal as well, leading to intermittent flooding. Pull that thing apart, take some pictures, and we'll walk you through it.

-Jay

jinman

Rest in Peace

- Joined

- Feb 23, 2001

- Messages

- 20,387

- Location

- Texas - Wise County - Sunset

- Tractor

- NHTC45D, NH LB75B, Ford Jubilee

If this thing is gravity fed, then it is highly likely that your carb is at fault.

-Jay

Yep, Jay, the carb may have a crankcase vent hose that is attached between the carb and the valve cover. If so, flooding gasoline could fill the carb and run down the vent tube and into the crankcase. I just think it is more likely getting into the crankcase this way rather than into the combustion chamber and by the piston rings.

That sounds like a good possibility.

I checked the model number on the motor and it says it is cv16s.

The carb has a plastic float in it, I don't remember it being adjustable though. I will take it apart again on sat. and take pictures. Do they make a rebuild kit for one of those little things? There isn't a whole lot of parts to it.

I checked the model number on the motor and it says it is cv16s.

The carb has a plastic float in it, I don't remember it being adjustable though. I will take it apart again on sat. and take pictures. Do they make a rebuild kit for one of those little things? There isn't a whole lot of parts to it.

jbarker855

Silver Member

You're right. Plastic floats are generally not adjustable. I would be surprised if you could not find parts for it.

jinman

Rest in Peace

- Joined

- Feb 23, 2001

- Messages

- 20,387

- Location

- Texas - Wise County - Sunset

- Tractor

- NHTC45D, NH LB75B, Ford Jubilee

I'm attaching a photo of your correct engine. The arrow is pointing to the breather hose I think might be the problem. Also, you should recheck the carb as you've stated you plan to do.

You can go to this website and enter as a guest. It has your engine and all the detailed parts diagrams you will ever need. You can't order from this site, but you can use it to find part numbers to order. I've already looked at the John Deere version of the CV16 engine this morning. Also, the "S" on the end of your model just means "electric start."

You can go to this website and enter as a guest. It has your engine and all the detailed parts diagrams you will ever need. You can't order from this site, but you can use it to find part numbers to order. I've already looked at the John Deere version of the CV16 engine this morning. Also, the "S" on the end of your model just means "electric start."

Attachments

J_J

Super Star Member

- Joined

- Sep 6, 2003

- Messages

- 18,952

- Location

- JACKSONVILLE, FL

- Tractor

- Power-Trac 1445, KUBOTA B-9200HST

The best advice here would be to install a fuel shutoff valve, and turn it off and let the carb run dry. I don't know if he said it had a fuel pump, but if it does, that is one possible leak. A vacuum checker can determine if the diaphragm is tight. The other source, is the needle is not fully seating, and flooding the carb and then leaking through the engine to the oil reservoir. and/or filling the muffler.

You can change the needle, but if the seat has corrosion on it, then the needle still won't seat. To remedy that, requires a small brass brush, small enough to reach into the cavity for the needle and rotate the brush around a bit. Using your finger to push on the float is not good enough to check the needle and seat. A lot of pressure will surely shut off the fuel. The best way to check the needle and seat is to let that small amount of fuel in the bowl to close off the fuel flow.

Do yourself a favor, and check the oil level before starting. If the fuel level in the tank is lower than it should be, find out where the fuel went. It either leaked on the ground, into the crankcase, or someone stole some fuel.

If you happen to get water in the engine from where ever, the water will settle to the bottom of the sump, and if you catch it before you crank the engine, you can prevent it from emulsifying and you have a mess. Never did figure out how the water got in the crankcase on some of my engines.

If your gas tank should empty into the crankcase, you might get what is called hydraulic lock, whereby the engine will start to turn and just lock up. Remedy is to just drain the oil, refill both, and use the fuel shut off on the engine, and let the engine run until it stops from lack of fuel. If you want to know how I know all this, it is that I have experienced these things, from 22 years of landscaping, using Kohler, Honda, and Briggs engines. Shut off the fuel and cover the engines is the best advice I can give.

You can change the needle, but if the seat has corrosion on it, then the needle still won't seat. To remedy that, requires a small brass brush, small enough to reach into the cavity for the needle and rotate the brush around a bit. Using your finger to push on the float is not good enough to check the needle and seat. A lot of pressure will surely shut off the fuel. The best way to check the needle and seat is to let that small amount of fuel in the bowl to close off the fuel flow.

Do yourself a favor, and check the oil level before starting. If the fuel level in the tank is lower than it should be, find out where the fuel went. It either leaked on the ground, into the crankcase, or someone stole some fuel.

If you happen to get water in the engine from where ever, the water will settle to the bottom of the sump, and if you catch it before you crank the engine, you can prevent it from emulsifying and you have a mess. Never did figure out how the water got in the crankcase on some of my engines.

If your gas tank should empty into the crankcase, you might get what is called hydraulic lock, whereby the engine will start to turn and just lock up. Remedy is to just drain the oil, refill both, and use the fuel shut off on the engine, and let the engine run until it stops from lack of fuel. If you want to know how I know all this, it is that I have experienced these things, from 22 years of landscaping, using Kohler, Honda, and Briggs engines. Shut off the fuel and cover the engines is the best advice I can give.