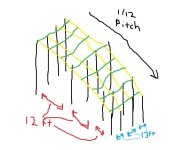

You may remember my thread on I-beams. Well I got a good deal on a semi load of 2 3/8" pipe so my plans on constructing my shed have changed. Instead of trying to make it clear span i have set 16 pipes in the ground to support the structure. I have attached a horrible drawing of what my plan is.

Basically the shed will be 36' wide and 39' feet deep. The pitch is in the 36' direction. With the 16 posts I have set in the ground (black on the drawing) the longest span for the purlin will be 13'. I plan on putting the purlins that the R panels will screw (green on my drawing) to on 4' centers so there will be a purlin centered over the pipes then two suspened in between the pipes by the purlins running in the direction of the pitch (yellow on the drawing).

I am guessing 4" purlins for the green ones will be plenty but I am wondering about the yellow ones if they need to be larger.

Basically the shed will be 36' wide and 39' feet deep. The pitch is in the 36' direction. With the 16 posts I have set in the ground (black on the drawing) the longest span for the purlin will be 13'. I plan on putting the purlins that the R panels will screw (green on my drawing) to on 4' centers so there will be a purlin centered over the pipes then two suspened in between the pipes by the purlins running in the direction of the pitch (yellow on the drawing).

I am guessing 4" purlins for the green ones will be plenty but I am wondering about the yellow ones if they need to be larger.