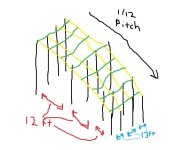

You may remember my thread on I-beams. Well I got a good deal on a semi load of 2 3/8" pipe so my plans on constructing my shed have changed. Instead of trying to make it clear span i have set 16 pipes in the ground to support the structure. I have attached a horrible drawing of what my plan is.

Basically the shed will be 36' wide and 39' feet deep. The pitch is in the 36' direction. With the 16 posts I have set in the ground (black on the drawing) the longest span for the purlin will be 13'. I plan on putting the purlins that the R panels will screw (green on my drawing) to on 4' centers so there will be a purlin centered over the pipes then two suspened in between the pipes by the purlins running in the direction of the pitch (yellow on the drawing).

I am guessing 4" purlins for the green ones will be plenty but I am wondering about the yellow ones if they need to be larger.

You can go thirteen feet spans with six inch fourteen gauge purlins without any problems.

Since you have two and three eighths posts I suggest you consider a method of construction that I've had good luck with. I would go with eight inch purlins and here's how I would do it.

I would cut off my posts to their finished height. Then I would drill through one edge of the eight inch purlin. Let's say you're looking at the purlin from the end. What you see is the C. Now imagine a piece of pipe coming through the bottom flange of the C to rest on the inside of the top flange of the C. This connection gives you an added mechanical advantage if the welding skills aren't as good as they could be. The most difficult part is lining up the holes to be drilled.

Drilling the holes is not an easy operation. What I use is a half inch DeWalt drill that's big and has two handles. Even with that leverage when the hole saw makes that last spin a lot of the time it will want to bind up and wrap you around the purlin. So don't tackle this with a small drill and whatever you do, make sure you're braced when doing it.

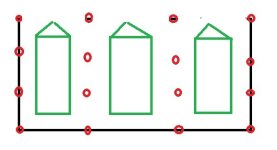

You can also use an old method of mine for doing the side walls using the same drilling process. You go through the four inch piece of the four inch purlin with the drill bit. Then you can slide the purlins down the pipes. Again, you get a mechanical advantage.

The four inch purlin with the four inch in a horizontal position gives you a couple of things the conventional four inch vertical location doesn't offer. One is it more than doubles your lateral strength. Vertical strength isn't a critical consideration because when your attach your metal sheeting to the purlin you've picked up ungawdly vertical strength. What you're wanting is lateral, in and out, strength.

Another thing is offers is an easier way to frame in windows and doors if desired. What's really cool about this is you don't have to go to a steel supply and pay their price for a pre-hung door or window. The horizontal orientation enables you to frame up a box store pre-hung door or window at a fraction of the price.

It's also great to have a wall framed this way if you're wanting to insulate or add sheeting on the inside. You can attach the siding to the outside edge of the purlin and then place standard insulation between the wall and your inside sheeting whether it's wood or metal.

You can click on my signature and search my site for some examples of what I'm talking about. You can also do some searches here on TBN and see more examples of it.

Keep in mind that engineers are like attorneys. Sometimes you need them.