I think I finally found an explanation that I could understand. This will probably be obvious to those familiar with hydraulics, but it really helped me understand what "power beyond" is all about.

First I checked my backhoe and found it has a Gresen series V12 valve. I contacted Parker Hydraulics and spoke with Mr. David Fabian, who was extremely helpful. First he identified the 2702 casting as an SP2 series valve, and explained some were made with power beyond capability and some did not have this option. If it has power beyond there will be another port located near the return to tank port, which my valve does not have.

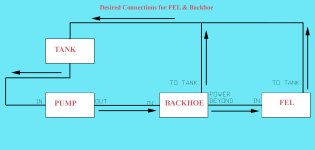

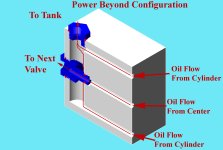

On the other hand, the V12 series does have power beyond capability, and just needs to be configured correctly. All that needs to be done is replace the open center plug with a "power beyond sleeve" in the conversion port located on the output end of the V12 series backhoe valve, and connect as shown in the attached diagram. Mr. Fabian then explained that the series connection I used would result in high pressure being applied to the tank port on the 2702 valve whenever the backhoe valves are actuated. This high pressure on the tank port is applied to the seals on the ends of the spools, causing them to leak and will eventually blow the seal.

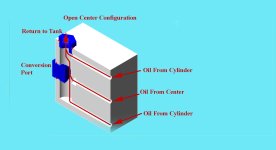

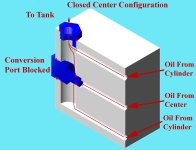

Mr Fabian explained the concept of configuring valves, and I sketched some simple 3d drawings showing the oil flow in each configuration. The sketches are only the output end of a generic valve but show how the V12 series is changed from one configuration to another. The three configurations I sketched are open center, closed center, and power beyond.

In all configurations the oil flow will be to the tank port when any valve is actuated, forcing oil to a cylinder. Likewise if the pressure relief valve opens (due to overpressure) the oil will flow to the tank port through another path not shown on my sketches. Therefore both the backhoe and FEL valves must have a return line connected back to the tank.

The difference in configurations only affects the oil that flows (or tries to flow) through the center of the spools when no cylinder is actuated.The standard configuration is open center, which means the oil flowing through the spools in the center (non-actuated) position is always returned to the tank port.

A closed center configuration blocks the oil flow in the center, causing the pressure at the inlet to rise to the level that the pressure relief valve opens (usually 1500-3000 PSI). This forces the pump to work hard all the time and wastes horsepower, but it allows a parallel connection of valves provided they are all closed center, with maximum pressure always available to all valves.

In the power beyond configuration, the center oil flow is diverted to a third port which is then connected in series with the next valve in the system. Note that if several valves are series connected, all valves except the last one in the series string must have power beyond configured. The last valve is open center, so when all valves are in the center position, oil will flow back to the tank with no high pressure produced anywhere in the system.

If any valve in the series string is actuated, the oil will be diverted through a cylinder at high enough pressure to move the cylinder, or if the cylinder cannot move (end of travel or too much load) then the oil will flow through the relief valve to the tank. Only one valve at a time may be actuated since the oil will be diverted through a cylinder and flow back to the tank rather than flowing through the power beyond line to the next valve (i.e. If backhoe is in use, no oil is sent to the FEL in my case).

I hope this will help another novice to understand the how and why of power beyond.