I have a 1999 NorTrac NT254 with Great Bend Loader and Backhoe.

While completely overloading the Backhoe trying to break a stump free (I know, I know), the bucket cylinder shaft bent 90 degrees. This is the cylinder that curls/crowds the bucket.

Today I called Northern Tool and was told that Great Bend has been bought out by Bush Hog. Northern Tool had a slightly different cylinder that "should work" for about $500. I wanted the exact cylinder so I called Bush Hog and was quite surprised to find out they want just under $1900 (yes, nineteen hundred) for a replacement cylinder.

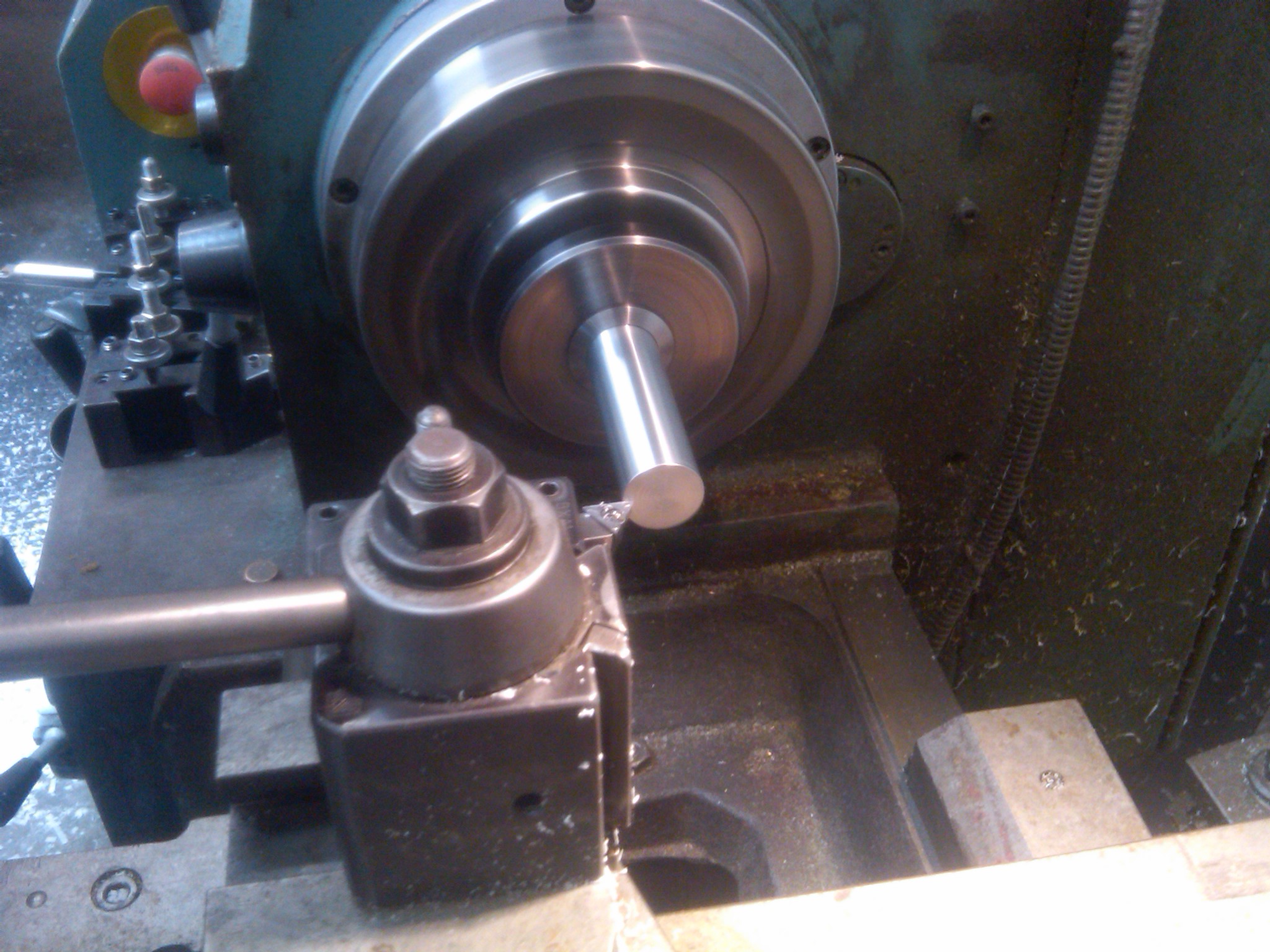

So now I am looking into having a new 4140 chrome shaft machined and welded to fit my existing cylinder.

I will also need to source new seals. Any suggestions are welcome.

Thanks,

Gene :^)

PS: Photos of a previous stump, not the culprit that got me this time.

While completely overloading the Backhoe trying to break a stump free (I know, I know), the bucket cylinder shaft bent 90 degrees. This is the cylinder that curls/crowds the bucket.

Today I called Northern Tool and was told that Great Bend has been bought out by Bush Hog. Northern Tool had a slightly different cylinder that "should work" for about $500. I wanted the exact cylinder so I called Bush Hog and was quite surprised to find out they want just under $1900 (yes, nineteen hundred) for a replacement cylinder.

So now I am looking into having a new 4140 chrome shaft machined and welded to fit my existing cylinder.

I will also need to source new seals. Any suggestions are welcome.

Thanks,

Gene :^)

PS: Photos of a previous stump, not the culprit that got me this time.