grsthegreat

Super Star Member

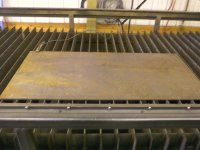

I went ahead and cut and welded up the device to move my smaller bumper pull trailers. i had a similar device on my old tractor, and it worked great for years.

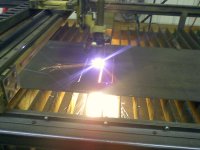

I simply gave up trying to use a receiver hitch device, because i could not get it to work without having to climb out of the cab to hook it up. As you can see in the previous post, i put a ball on permanent to the bucket. tested it and it worked great. I'm sure glad i filled the rear tires. this trailer did its best to try and lift the tractor up. Man this trailer is heavy. Ill use this for my goose neck trailers only

i tested this one pictured above....worked great. didn't have to climb out of the cab.

i simply pin it to hole in bucket when needed.

I simply gave up trying to use a receiver hitch device, because i could not get it to work without having to climb out of the cab to hook it up. As you can see in the previous post, i put a ball on permanent to the bucket. tested it and it worked great. I'm sure glad i filled the rear tires. this trailer did its best to try and lift the tractor up. Man this trailer is heavy. Ill use this for my goose neck trailers only

i tested this one pictured above....worked great. didn't have to climb out of the cab.

i simply pin it to hole in bucket when needed.