You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Loader Adjusting the relief valve

- Thread starter mfuller

- Start date

- Views: 70066

More options

Who Replied?

/ Adjusting the relief valve

#1

Hooked_on_HP

Veteran Member

Which one. Loader or TPH.

Bill

Bill

jinman

Rest in Peace

- Joined

- Feb 23, 2001

- Messages

- 21,059

- Location

- Texas - Wise County - Sunset

- Tractor

- NHTC45D, NH LB75B, Ford Jubilee

Mark, I'm very concerned about your adjusting the pressure on your hydraulic pump. If you are having decreased flow and speed on your backhoe, the pressure adjustment will do you no good. If you need more power, the higher pressure would help, but at the danger of blowing seals or the hydraulic pump seal and flooding your engine with fluid.

The very first thing you need to do is use that new port and check the pressure with a gage. Compare that pressure to the factory spec and determine if your pump pressure is low. I'm guessing your pressure is probably around 2200 psi, maybe even less. Does the manual you have show the spec'd pressure?

With all that said and warnings given, right in front of your right foot rest is a block where the loader's hydraulic lines attach. It's called the System Diverter Valve. On the bottom of that block is a large hex nut. Removing that nut will remove the pressure relief valve. You can order a shim kit to increase pressure by adding shims (about 150 psi per shim). PLEASE, PLEASE don't do this without knowing exactly what your current pressure is and if it needs increasing to meet the spec. That's the best advice I can give.

The very first thing you need to do is use that new port and check the pressure with a gage. Compare that pressure to the factory spec and determine if your pump pressure is low. I'm guessing your pressure is probably around 2200 psi, maybe even less. Does the manual you have show the spec'd pressure?

With all that said and warnings given, right in front of your right foot rest is a block where the loader's hydraulic lines attach. It's called the System Diverter Valve. On the bottom of that block is a large hex nut. Removing that nut will remove the pressure relief valve. You can order a shim kit to increase pressure by adding shims (about 150 psi per shim). PLEASE, PLEASE don't do this without knowing exactly what your current pressure is and if it needs increasing to meet the spec. That's the best advice I can give.

RickB

Super Star Member

- Joined

- Sep 18, 2000

- Messages

- 15,190

- Location

- Up the road from Dollar General WNC

- Tractor

- Just a Scag

Does anyone know where or how to adjust the relief valve on my 1710?

Yes .

JC-jetro

Elite Member

Does anyone know where or how to adjust the relief valve on my 1710?

Mark,

It seems your 1710 hyd is pretty close to my 1700. Take a look at the thread below and you'll find what you need. It is lengthy discussion, you might directly go to the 3rd page of the discussion although there is plenty of good info there.

I would not increase the pressure unless you're way below the specs.

JC,

http://www.tractorbynet.com/forums/new-holland-owning-operating/130597-adjust-not-adjust.html

Harry in Ky

Veteran Member

If you're asking for help and advise, you might start by describing the problem, and why you feel the need to adjust the relief in the first place. On most of the NH compacts the relief is one item that rarely needs adjustment.

Harry, here's my problem. I've got a 1710 with a 770B loader. The loader seems a little weak, It won't raise the front wheels off the ground unless you place it flat on the ground, then use the bucket dump to raise it (kinda cheating). Not sure if this is normal. I recently added a GB 651 backhoe that came with a self contained pump rated at 2250 psi. I removed the pump and reservoir and plumbed it directly into the tractor 3PH hydraulics. The hoe seems to be around 10% weaker, when running off the tractor hydraulics. Now, the tractor hydraulics are specd at 2133 psi. The loader is specd at 1600. I agree, I do need to check the system pressure before adjusting anything, but I didn't want to buy a pressure gauge if adjustment wasn't possible anyway. I have the loader manual and it shows an inline pressure relief valve, but I cannot find it on my setup. I wasn't sure if someone simply lowered the whole system pressure to accomplish this. JC, wonderful schematic on that post. Bill, I didn't realize there was another relief valve for the 3pt. I see that in JC's schematic. So, now that I know it is adjustable, I will pick up a gauge tomorrow. If it is below spec, I assume it will be cause the pump is worn. Is it normal to simply shim up the relief valve, or will the pump need repair?

JC-jetro

Elite Member

Mark,

if the pump is tired adding shims would only add to it's misery and it will blow a seal. a blown seal and tractor running will sure enough kill the pump. Your hyd system is live, your pump will turn even if you are not using any hydraulic driven implement or 3 point system. A gear type positive displacement pump will destroy itself in a short time without lubrication.

Buy a liq. filled gauge up to 5000 psi from Northern under $25. that's a great investment, see where your system relieves pressure at. That is your pressure. need to go a bit higher than the top notch and relief valve will start chattering. if your are less than I think 2133 psi ?? then by all means raise it some. don't need to have a shim here as you have adjustment screw under the relief device cap. You shim if you don't have the adjustment screw.

JC,

if the pump is tired adding shims would only add to it's misery and it will blow a seal. a blown seal and tractor running will sure enough kill the pump. Your hyd system is live, your pump will turn even if you are not using any hydraulic driven implement or 3 point system. A gear type positive displacement pump will destroy itself in a short time without lubrication.

Buy a liq. filled gauge up to 5000 psi from Northern under $25. that's a great investment, see where your system relieves pressure at. That is your pressure. need to go a bit higher than the top notch and relief valve will start chattering. if your are less than I think 2133 psi ?? then by all means raise it some. don't need to have a shim here as you have adjustment screw under the relief device cap. You shim if you don't have the adjustment screw.

JC,

Last edited:

jinman

Rest in Peace

- Joined

- Feb 23, 2001

- Messages

- 21,059

- Location

- Texas - Wise County - Sunset

- Tractor

- NHTC45D, NH LB75B, Ford Jubilee

Buy a liq. filled gauge up to 5000 psi from Northern under $25. that's a great investment, see where your system relieves pressure at. That is your pressure. need to go a bit higher than the top notch and relief valve will start chattering. if your are less than I think 2133 psi ?? then by all means raise it some. don't need to have a shim here as you have adjustment screw under the relief device cap. You shim if you don't have the adjustment screw.

JC,

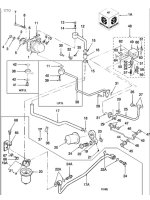

JC, are you talking about the valve circled in red on the photo below? I believe this valve has the output of the main hydraulic pump routed to it. It's the valve with the pressure relief on the bottom and has a shim kit listed in New Holland's parts list. If it is set at a low value, any relief valve after it will not be able to raise the pressure. It's possible that your tractor doesn't have this since I think these were not added until later in the model line.

Attachments

JC-jetro

Elite Member

JC, are you talking about the valve circled in red on the photo below? I believe this valve has the output of the main hydraulic pump routed to it. It's the valve with the pressure relief on the bottom and has a shim kit listed in New Holland's parts list. If it is set at a low value, any relief valve after it will not be able to raise the pressure. It's possible that your tractor doesn't have this since I think these were not added until later in the model line.

Jim,

You are right and I do not have the block you have circled. I'm sure that is for the later model with a loader. I can't see two relief pressure in series unless there is a design reasons for it. On high pressure steam line I reduce it on several different levels based on design need ( 100 psi or lower for steam to hot conversion, to 30 psis for sterilization and around 10 psi for humidification). I don't know if in tractor hydraulics they do the same or not. Obviously here you want the highest pressure and flow available to loader and then 3 point system.

I wanted to stress Mark that there is always a way to up the pressure either adjustment or shimming but should not attempt it unless he knows and verified operating pressure. On mine , if I had a loader then the extra loader hyd block would be sandwiched between the relief device and the lift spool. In that case there would be only one adjustable relief device. I think somewhere in my thread I have a pic of 1700 relief device that Mark can check.

JC,

jinman

Rest in Peace

- Joined

- Feb 23, 2001

- Messages

- 21,059

- Location

- Texas - Wise County - Sunset

- Tractor

- NHTC45D, NH LB75B, Ford Jubilee

Yes JC, the 1710 models after 1983 had the pressure relief block (diverter valve actually). Once that pressure is set, any additional pressure relief can only adjust the pressure lower. Here is a hydraulic diagram of the 1710 with item 48 being the diverter block. The pressure adjusting shim kit is item #58.

Attachments

JC-jetro

Elite Member

Yes JC, the 1710 models after 1983 had the pressure relief block (diverter valve actually). Once that pressure is set, any additional pressure relief can only adjust the pressure lower. Here is a hydraulic diagram of the 1710 with item 48 being the diverter block. The pressure adjusting shim kit is item #58.

Good info Jim:thumbsup:, I'll be curious to see if he has the additional relief device, most probably not. Mark now should have all he need to evaluate the situation and adjust the pressure if it is warranted.

JC,

mostly_gas

Super Member

mfuller, You not only need pressure but volume as well. There was a reason the backhoe had it's own pump. I would not be surprised the pump you took off had a larger flow rate and that accounts for the speed difference.

I have a 1700 w/ 770 loader and it does the same thing , not enough force from the main lift cylinders to raise the front end, but the curl cylinders will.

I have a 1700 w/ 770 loader and it does the same thing , not enough force from the main lift cylinders to raise the front end, but the curl cylinders will.

Sorry it's been so long between posts. I've worked 12 hrs overtime this week so far. OK, I got a gauge, checked the pressure coming out of the aux port. With the rpm's about midrange, the gauge reads 1700 psi. The loader is rated at 1600 psi. I do have the diverter valve circled in red. Mostly Gas, the self contained pump was rated for 4.5 gpm, my 1710 is rated for 7.8 gpm. But, I'm not as concerned with the speed as much with force. I know that relief valves in series can only reduce the pressure, not increase it. My big question now is, how do they get the full 2133 psi of pressure to the 3ph if the diverter valve for the loader drops it to 1600-1700 psi?

JC-jetro

Elite Member

Sorry it's been so long between posts. I've worked 12 hrs overtime this week so far. OK, I got a gauge, checked the pressure coming out of the aux port. With the rpm's about midrange, the gauge reads 1700 psi. The loader is rated at 1600 psi. I do have the diverter valve circled in red. Mostly Gas, the self contained pump was rated for 4.5 gpm, my 1710 is rated for 7.8 gpm. But, I'm not as concerned with the speed as much with force. I know that relief valves in series can only reduce the pressure, not increase it. My big question now is, how do they get the full 2133 psi of pressure to the 3ph if the diverter valve for the loader drops it to 1600-1700 psi?

Mark,

Let's verify first if you have a relief device passed your diverter valve. look at the pic below, do you have them on your 1710?

If you do and diverter comes first then You'll have an issue, as you can keep stepping the pressure down but once down can't step up real easy. follow plumbing and inlet and out let to the pump and see where your reliefs are. I would think you might have a main relief like pictured below to 2133 psi and diverted block steps it down to your loader requirement at 1600. doing so you'll have max rated pressure and flow for the 3 point implement and a lower pressure for the loader. I'm heading back home and should be able to post back later tonight if you have a question.

JC

My tractor does not have that relief valve. It has a 3 bolt cover bolted on there. I was reading my loader manual earlier, it states that the loader can be used on a 1910 at full pressure (2133) or on the 1310,1510,1710 with an inline relief valve, which mine does not have. It also states that some of the remote controls for the loaders have a built in relief valve. Are we sure there is a relief valve built into the diverter block next to my right foot?

JC-jetro

Elite Member

My tractor does not have that relief valve. It has a 3 bolt cover bolted on there. I was reading my loader manual earlier, it states that the loader can be used on a 1910 at full pressure (2133) or on the 1310,1510,1710 with an inline relief valve, which mine does not have. It also states that some of the remote controls for the loaders have a built in relief valve. Are we sure there is a relief valve built into the diverter block next to my right foot?

Mark,

You must have a relief valve somewhere downstream of your hyd pump before any branches or implements. there are two reasons for it. What establishes system pressure is an obstruction to cause the pressure (adjustable) on a gear pump. Secondly this pressure needs to be controlled (maintained constant) so you would not dead head a positive displacement pump, that's where the relief comes. Spring in the relief maintains adjustable system pressure and above that it relives to maintain max pressure. Pump internal mechanism including seals are designed for a pressure so if you go above it it can damage it. You must have an adjustable relief as party of you hyd block like Jim stated. Shimming in the diverter block would increase your system pressure.

JC,

Hey, all. Just an update. I added couple of shims to the relief valve in the diverter block. Pressure went from 1700 to about 2150. The back hoe now works much better. I did, however, blow a hose on the hoe, but, if it couldn't handle 2150 psi it needed replacing. The hose was rated for 3000 psi, I went ahead and replaced it with a 4000 psi hose. If anymore go I will replace them with the better hose also.

Thanks to all those who offered advice. It sure made it a lot easier.

Thanks to all those who offered advice. It sure made it a lot easier.

Here are some similar links:

- Replies

- 11

- Views

- 2K