You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Big ride on mower

- Thread starter AndyUK

- Start date

- Views: 42393

More options

Who Replied?

/ Big ride on mower

#31

Renze

Super Member

well work is a bit quiet at the moment, just working half days gives more toy time lol

whats this volvo 440 dirt buggy l see in your signature ???

Andy

http://www.tractorbynet.com/forums/build-yourself/105561-building-dirt-buggy.html

Project never finished. Its still under a tarp in a dead corner between some pig barns.

madmax12

Veteran Member

Renze said:http://www.tractorbynet.com/forums/build-yourself/105561-building-dirt-buggy.html

Project never finished. Its still under a tarp in a dead corner between some pig barns.

We all do that in some part of our life. Seems like the older I get the longer the list gets. Hard to prioritize. For me, I'm tryin to start my list like this, though I don't even think I do this part right either: The Living God, family, others, self, stuff...

The stuff is a never ending very long list...

I just sold a motorcycle I've been meaning to get to for over a decade... I was never gonna get to it... Now I don't have to.

Last edited:

AndyUK

Bronze Member

How are you going to power the mower decks?

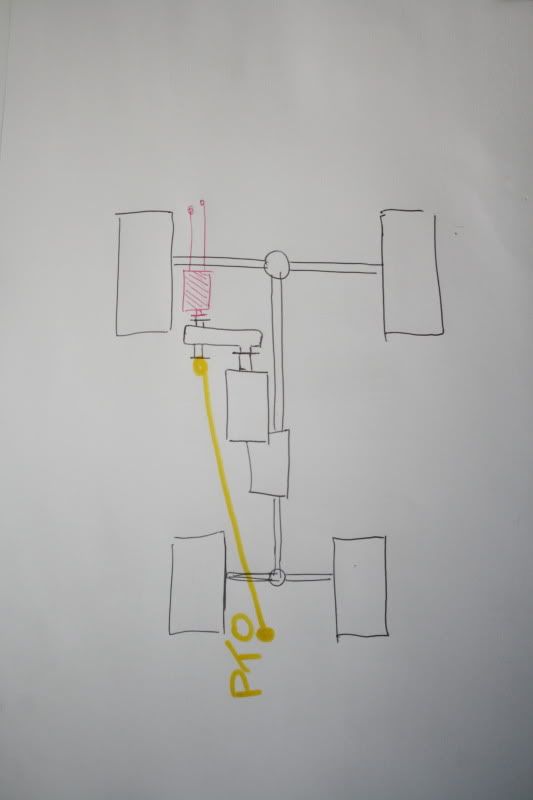

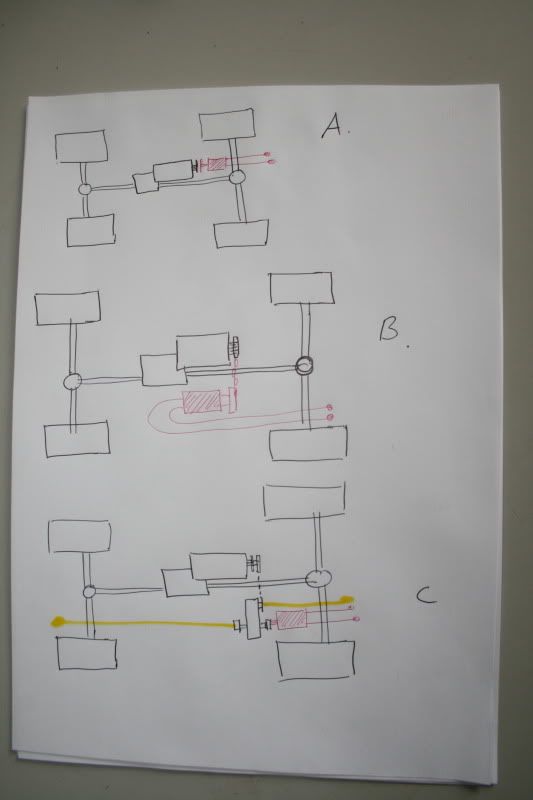

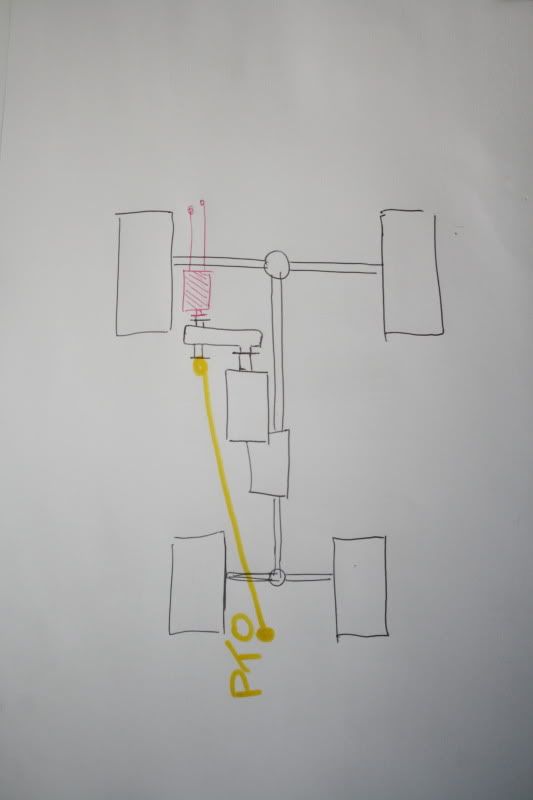

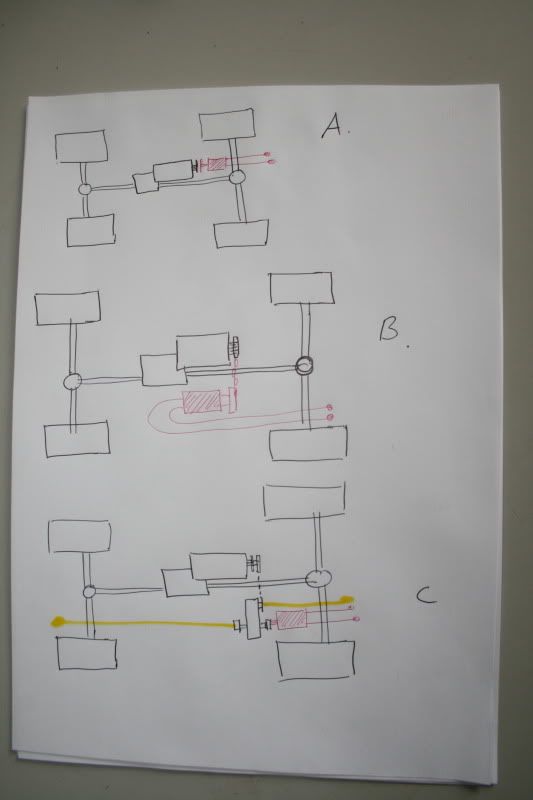

well l was thinking that a driveshaft running straight off the front crank pulley out to the cutting deck would be simplest and l like simple as what you havent got wont break !!

but that links the cutting deck directly to engine speed and is a bit inflexable, l think that aczlan is right when he say hydraulic drive has some benifits and perhaps this is the way l should go

mounting a hyd pump infront of the crank pulley (A) is the easiest construction wise but l may have a direction of rotation issue there and no way of disconnecting the pump when l am not using the cutters

(B) would solve the direction issue by chain driving across to the pump but again l have no way of disconnecting the pump drive when l want to

and (C) looks like it has possibilities, a standard suzuki sj transfer box will give me 2 ratios to alter the speed of the pump and also 2 pto out puts, front one at engine speed and the rear one at engine speed or half engine speed but what l like is l can put the transfer box into neutral and disconnect the pump when its not wanted

the bit l dont like is the chain drive across the vehicle around the front drive shaft, so expanding that further switch the sj transfer to the other side and direct drive into it, the pump will probally need to mount on the back of the transfer box to get the rotation right

this means l will have to relocate the power steering pump and maybe altenator but that is all doable

AndyUK

Bronze Member

I like the bendy tubes :thumbsup:

I should come and see you when I get working on the trike again.

hi woodsmith

you can come see me anytime, infact l will be in manchester next week, openshaw where ever that is l havent looked yet,

if you need some rolled tube for your trike its no problem at all, l have only made 1.5" tooling for my roller

so inch and a half dia tube is all l can do at present but my pal is building a buggy that needs some 1.75 dia rolling soon so l might be making some more tooling

cheers Andy

AndyUK

Bronze Member

http://www.tractorbynet.com/forums/build-yourself/105561-building-dirt-buggy.html

Project never finished. Its still under a tarp in a dead corner between some pig barns.

nice, what diesel engine did volvo use back then ? was it their own or maybe VW ? buggys always get my attention lol and a diesel auto one appeals to me, might try that although an electric buggy also has some appeal

l built one out of an old MGF some time back, l know thats cheating as it was a rear engined car anyway and things like the hand brake and gearchange are all sorted out for you lol

l used the hydro suspension as well, seemed to work well and smooth out the bumps

heres a couple of pics from 3 or 4 years ago

and then some time later l sold it to a pal of mine who changed the colours, added a few tubes and different graphics and still uses it today

here he is chasing my current buggy which is the orange one in the background of some of the mower pics

buggy - YouTube

Last edited:

Renze

Super Member

Renault 1.9 turbodiesel with intercooler. But turbo manifolds etcetera were re engineered towards Volvo spec with Porsche engineering, just like the other small Renault engines Volvo used at that time. In fact most people that race a Renault 5 turbo, use the 1.7 turbo engine from the 480 turbo instead of the Renault 1.5 turbo because its so easy to tune to over 200hp (where the Volvo 480 only had 122hp but truck-like torque figures)nice, what diesel engine did volvo use back then ? was it their own or maybe VW ? buggys always get my attention lol and a diesel auto one appeals to me, might try that although an electric buggy also has some appeal

Yes thats where we left... brake pedal, steering column in place, but fuel tank, brake lines, gearstick etcetera we never had time or sense to start on that part..l built one out of an old MGF some time back, l know thats cheating as it was a rear engined car anyway and things like the hand brake and gearchange are all sorted out for you lol

aczlan

Good Morning

- Joined

- Mar 7, 2008

- Messages

- 17,540

- Tractor

- Kubota L3830GST, B7500HST, BX2660. Formerly: Case 480F LL, David Brown 880UE

Open center hydraulics with a large diameter valve? That would give you overload protection via a pressure relief valve and on/off for the deck(s). Would also allow rear/side attachments if desired.(B) would solve the direction issue by chain driving across to the pump but again l have no way of disconnecting the pump drive when l want to

Aaron Z

AndyUK

Bronze Member

Open center hydraulics with a large diameter valve? That would give you overload protection via a pressure relief valve and on/off for the deck(s). Would also allow rear/side attachments if desired.

Aaron Z

you are going to have to help me with the hydraulics bit as l am not clued up on them,

open centre would be where the inlet or pressure port is connected to the outlet and hence tank when the lever is in the middle position ? and does the lever stay in any of the 3 positions forwards,backwards and centre/off ?? every valve l have used has been spring loaded to centre

Andy

I am worried that your ground speed will be too fast at the proper speed to for the mower decks run. How close are you too a test drive?well l was thinking that a driveshaft running straight off the front crank pulley out to the cutting deck would be simplest and l like simple as what you havent got wont break !!

but that links the cutting deck directly to engine speed and is a bit inflexable, l think that aczlan is right when he say hydraulic drive has some benifits and perhaps this is the way l should go

mounting a hyd pump infront of the crank pulley (A) is the easiest construction wise but l may have a direction of rotation issue there and no way of disconnecting the pump when l am not using the cutters

(B) would solve the direction issue by chain driving across to the pump but again l have no way of disconnecting the pump drive when l want to

and (C) looks like it has possibilities, a standard suzuki sj transfer box will give me 2 ratios to alter the speed of the pump and also 2 pto out puts, front one at engine speed and the rear one at engine speed or half engine speed but what l like is l can put the transfer box into neutral and disconnect the pump when its not wanted

the bit l dont like is the chain drive across the vehicle around the front drive shaft, so expanding that further switch the sj transfer to the other side and direct drive into it, the pump will probally need to mount on the back of the transfer box to get the rotation right

this means l will have to relocate the power steering pump and maybe altenator but that is all doable