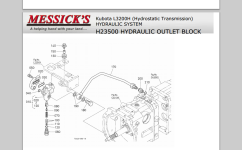

The PB from the new valve should return to the hyd block if it looks like the picture.

FEL out line is going to tank if the adapter blk looks like the last pic I posted.

The OUT or return lines can all be teed together.

Will have to see your pic of hyd blk to advise more.

If you have to cut and swage, it is not difficult at all.

Excerpts

Open center circuits use pumps which supply a continuous flow. The flow is returned to tank through the control valve's open center; that is, when the control valve is centered, it provides an open return path to tank and the fluid is not pumped to a high pressure. Otherwise, if the control valve is actuated it routes fluid to and from an actuator and tank. The fluid's pressure will rise to meet any resistance, since the pump has a constant output. If the pressure rises too high, fluid returns to tank through a pressure relief valve. Multiple control valves may be stacked in series [1]. This type of circuit can use inexpensive, constant displacement pumps.

Closed center circuits supply full pressure to the control valves, whether any valves are actuated or not. The pumps vary their flow rate, pumping very little hydraulic fluid until the operator actuates a valve. The valve's spool therefore doesn't need an open center return path to tank. Multiple valves can be connected in a parallel arrangement and system pressure is equal for all valves.