ptgdigger

Silver Member

I would say the Ebay seller put the wrong rings in your kit and I wouldn't ask him for the right one cause they seem like junk, and I still think the #1 rings are sprung or something, good cast iron rings as loose as they are on #1piston would have snapped if they were overexpanded that much.

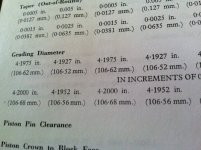

Ideally as Duroc said you would fix this engine for another lifetime by going with bore/proper oversize pistons and rings, sometimes life shoots the ideal solution in the foot. In that case I would order an oversize ring set from YT, their separate ring sets appear to come from Hastings , which are very good rings. I'd also order the upper gasket set , you need the head and valve cover and you should get some better valve stem seals with their kit as well. Keep in mind you have to check all the ring gaps , anything less than the specs you listed earlier needs a little very careful grinding. Going below the minimum gap will result in broken rings and a heavy dose of wallet punishment.

EDIT: The new pistons are Std bore? Sorry I missed that, saw the post where you measured them but the numbers didn't register in my brain , skip the underlined part above , the max oversize you can run on a std piston is .010, you're gonna need an oversize piston/ring kit.

Ray

Ideally as Duroc said you would fix this engine for another lifetime by going with bore/proper oversize pistons and rings, sometimes life shoots the ideal solution in the foot. In that case I would order an oversize ring set from YT, their separate ring sets appear to come from Hastings , which are very good rings. I'd also order the upper gasket set , you need the head and valve cover and you should get some better valve stem seals with their kit as well. Keep in mind you have to check all the ring gaps , anything less than the specs you listed earlier needs a little very careful grinding. Going below the minimum gap will result in broken rings and a heavy dose of wallet punishment.

EDIT: The new pistons are Std bore? Sorry I missed that, saw the post where you measured them but the numbers didn't register in my brain , skip the underlined part above , the max oversize you can run on a std piston is .010, you're gonna need an oversize piston/ring kit.

Ray

Last edited: