deereman75

Veteran Member

- Joined

- Apr 29, 2011

- Messages

- 1,912

- Location

- canada

- Tractor

- Deere 2120, Warner & Swasey 6000# offroad forklift, Case W9B loader, various non-running decorations

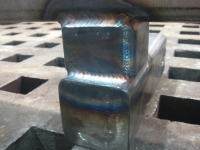

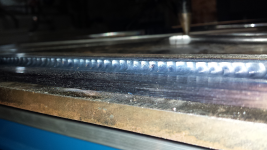

I have finally got started with tig welding, but I am having a really hard time with the tungsten and work turning black.

A few questions to start with. First, will a contaminated tungsten cause the work to be dull, black, and seem not shielded? Second, how far should the tungsten stick out of the cup? I have it around 3/8 of an inch. Third, would a 1/16 tungsten because overheating at 85 amps?

Also, can using a piece of clear vinyl tubing for gas hose cause an issue? It holds out pressure fine, but it was designed more for water than argon.... It was all I could get at the hardware store, and the only semi welding supply place didn't have anything.

Finally, how far should the tungsten be held from the work while welding?

I have already been suggested to use a bigger tungsten, and try using reading glasses. I will get both of those before using any more of my argon.

Any other tricks, tips, and suggestions?

I don't really want to burn any more argon before I have some idea what I'm doing wrong.

A few questions to start with. First, will a contaminated tungsten cause the work to be dull, black, and seem not shielded? Second, how far should the tungsten stick out of the cup? I have it around 3/8 of an inch. Third, would a 1/16 tungsten because overheating at 85 amps?

Also, can using a piece of clear vinyl tubing for gas hose cause an issue? It holds out pressure fine, but it was designed more for water than argon.... It was all I could get at the hardware store, and the only semi welding supply place didn't have anything.

Finally, how far should the tungsten be held from the work while welding?

I have already been suggested to use a bigger tungsten, and try using reading glasses. I will get both of those before using any more of my argon.

Any other tricks, tips, and suggestions?

I don't really want to burn any more argon before I have some idea what I'm doing wrong.