yomax4

Elite Member

- Joined

- Mar 11, 2007

- Messages

- 2,849

- Location

- Midwest

- Tractor

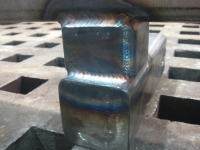

- ISEKI TA 247. Stihl Saws Gravely Zt's Polaris ATV's State Of The Art Welding Equipment

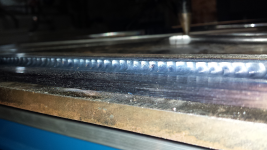

I am using thorinated tungsten. DCEN, 20 cfh argon.

I am going to talk to a master welder/machinist friend of mine this weekend, and see what he thinks.

I am going to see about getting a lesson or two from him.

If you are holding the correct arc length like you said 1/16 or so and you have no porosity , it has to be the base metal..steel tig welding is all about the material being clean..it's just as bad as aluminum for contamination. The only other thing that comes to mind is the wrong gas. Any chance they gave you a 75/25? Or a bad argon tank..you just don't have steel tig issues if all is clean. You didn't mention filler metal..are you just putting down beads or are you actually joining.?