ericher69

Veteran Member

On a garden tractor probably a very low grade casting. What makes you think it is cast steel? Figuring out what it's made off is the most important thing to know in order to repair it. Cast steel is much easier to weld than cast iron and cast aluminum is an entirely different animal so comparing how it welds is a moot point. Too much gas flow can also cause turbulence which can cause porosity. TIG is best for cast aluminum but for cast steel, I'd use stick 7018 but MIG would also work. 6013 is the last thing I would use on just about anything. Preheat is good on anything that's cast.

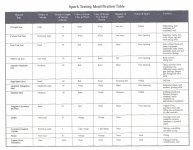

I used the grinder on the part and some angle mild steel and the sparks where identical which leads me to believe it is cast steel (no expert)

What would the sparks from grinding manganese look like?

MIG ended up getting it after grinding the porous weld and re-welding.