Ilikeurtractor

Veteran Member

- Joined

- May 16, 2011

- Messages

- 1,070

- Tractor

- Iseki TX1300F/TX1500/ TX2160F/TS2220F/ Satoh S370D/S373D

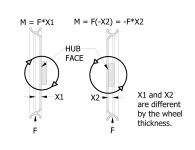

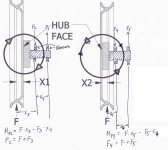

Attached is a diagram from a manufacturer's operating manual showing the front wheels in their respective "dished-in" and "dished-out" positions. I'm not for sure what it does for bearing wear (I can understand the OP's argument though that the magnitude of the torque shouldn't be more just whether it is positive or negative) but I know the tractor steering wheel is much more difficult to turn when the front wheels are at their wider position.