You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

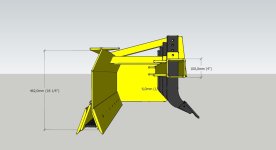

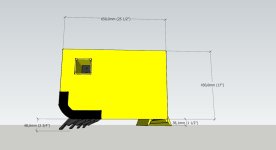

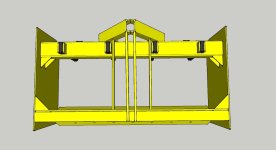

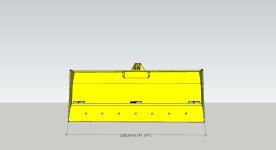

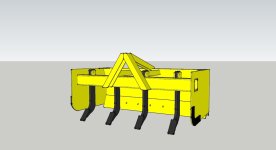

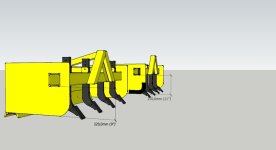

Rushy's box blade project (4 ft, hinged back)

- Thread starter Rushy11

- Start date

- Views: 8253

/ Rushy's box blade project (4 ft, hinged back)

#11

petes

Silver Member

- Joined

- Dec 26, 2009

- Messages

- 108

- Location

- Bellingham, Washington

- Tractor

- Kubota B8200 (21hp) , IH B275 (28hp), JD 1830 (68hp)

A few comments from one who built and has used a similar sized boxblade:

The scarifiers look thin to me. They'll see significant side loads and twisting forces when turning the tractor, and when they are hitting rocks/roots, etc. I'd recommend at least 12mm (1/2") or thicker material. You also may want to weld a "shovel" face on them to make the tips wider, ideally out of hard material.. The scarifiers purpose is to break up and lift the ground, not just to slice it.

I think the cutting edge angle is too steep. You want it to shave the earth, not shear it. I set my cutting edges at 45 degrees and that seem about right.

The top rear of the box doesn't have to be curved forward, unless you're using that bend to stiffen it, but it'd be easier to fabricate with just a flat back and weld a piece of tubing or angle across the top to stiffen it. The box doesn't keep curling the material like a snow plow... it fills up from the bottom up and the material just slides along the ground.

I'd make it so the cutting edge is just slightly below the sides, ~12mm (1/2"). You generally don't want the blade to take a big bite. The sides help control the depth of cut.

Oh, and plan to incorporate a trailer hitch on the back. It comes in very handy. My boxblade stays on my tractor all the time unless I have to use another implement, and being able to lift a trailer on the 3pt without having to remove the boxblade is pretty handy.

Just my thoughts and feedback on your design... take them or leave them.

Have fun building!

The scarifiers look thin to me. They'll see significant side loads and twisting forces when turning the tractor, and when they are hitting rocks/roots, etc. I'd recommend at least 12mm (1/2") or thicker material. You also may want to weld a "shovel" face on them to make the tips wider, ideally out of hard material.. The scarifiers purpose is to break up and lift the ground, not just to slice it.

I think the cutting edge angle is too steep. You want it to shave the earth, not shear it. I set my cutting edges at 45 degrees and that seem about right.

The top rear of the box doesn't have to be curved forward, unless you're using that bend to stiffen it, but it'd be easier to fabricate with just a flat back and weld a piece of tubing or angle across the top to stiffen it. The box doesn't keep curling the material like a snow plow... it fills up from the bottom up and the material just slides along the ground.

I'd make it so the cutting edge is just slightly below the sides, ~12mm (1/2"). You generally don't want the blade to take a big bite. The sides help control the depth of cut.

Oh, and plan to incorporate a trailer hitch on the back. It comes in very handy. My boxblade stays on my tractor all the time unless I have to use another implement, and being able to lift a trailer on the 3pt without having to remove the boxblade is pretty handy.

Just my thoughts and feedback on your design... take them or leave them.

Have fun building!

A few comments from one who built and has used a similar sized boxblade:

The scarifiers look thin to me. They'll see significant side loads and twisting forces when turning the tractor, and when they are hitting rocks/roots, etc. I'd recommend at least 12mm (1/2") or thicker material. You also may want to weld a "shovel" face on them to make the tips wider, ideally out of hard material.. The scarifiers purpose is to break up and lift the ground, not just to slice it.

I think the cutting edge angle is too steep. You want it to shave the earth, not shear it. I set my cutting edges at 45 degrees and that seem about right.

The top rear of the box doesn't have to be curved forward, unless you're using that bend to stiffen it, but it'd be easier to fabricate with just a flat back and weld a piece of tubing or angle across the top to stiffen it. The box doesn't keep curling the material like a snow plow... it fills up from the bottom up and the material just slides along the ground.

I'd make it so the cutting edge is just slightly below the sides, ~12mm (1/2"). You generally don't want the blade to take a big bite. The sides help control the depth of cut.

Oh, and plan to incorporate a trailer hitch on the back. It comes in very handy. My boxblade stays on my tractor all the time unless I have to use another implement, and being able to lift a trailer on the 3pt without having to remove the boxblade is pretty handy.

Just my thoughts and feedback on your design... take them or leave them.

Have fun building!

Thanks a lot for your tips!

-unfortunately you can't get proper ripper shanks in Germany, as no one has got a box blade like you guys have. The shanks in my draft are from a rotary harrow for preparing potato paddocks. The flat steel is 12x50mm and is the closest one i could find. Otherwise i have to let them cut by an engineer from proper steel. Generally i try do take common parts as it saves me time and are easy to replace just in case it breaks down or wears out. Btw: i wonder if it is cheaper to import a few shanks plus a set of spare one from the states, i have seen some for 17$ each? The shanks wich propose to use are 34 US$ each....

- yeah, the idea of an hitch makes sense. I thought about to put my steel roller behind the blade to compact the loose dirt immediately in the lower spots that the blade doesn't cut any deeper in the next pass. Makes that any sense?

Have you got any pictures of your blade? That would be great.

Cheers

Rushy

alia176

Silver Member

Rushy,

The moment arm on those teeth might be too much unless you lower the square tubing cross brace. I fear they will either bend or deform the cross brace under load!

The moment arm on those teeth might be too much unless you lower the square tubing cross brace. I fear they will either bend or deform the cross brace under load!

sparc

Veteran Member

- Joined

- Oct 2, 2011

- Messages

- 1,078

- Location

- NJ

- Tractor

- JD 4410, NH TC-25, Bobcat M610, JD X534, Dig-It Model 158, JD Ztrak 737. 6X4 Gator

Rushy,

The moment arm on those teeth might be too much unless you lower the square tubing cross brace. I fear they will either bend or deform the cross brace under load!

Good point, and i think with the tube steel that high it will tend to cause the box blade to roll up rather thandig in. Lowering the tube steel will be better. Look at manufactured box blades and see how high theirs are.

Hi,

i found a supplier for scarifier tynes in Germany and modified the design of the box blade a bit to fit the tynes. What do you think about this design?

Cheers

rushy

It looks good. I would cap off the main tube to keep stuff out of it. Are you going to make the hinged back so you can lock it in place to function like a fixed back.

Big Barn

Super Member

- Joined

- Aug 20, 2013

- Messages

- 6,874

- Location

- Victoria, B C

- Tractor

- More than 40 over the years. Ten at any one time. Mostly Ford and New Holland

I also agree. Looks like there will be too much leverage on the shanks with that design. A lower or second crossbrace would probably help. Good luck and have fun! TerryRushy, The moment arm on those teeth might be too much unless you lower the square tubing cross brace. I fear they will either bend or deform the cross brace under load!

I see you have already done that! Looks good!

Baby Grand

Elite Member

- Joined

- Nov 12, 2007

- Messages

- 4,649

- Location

- Windsor, CT.

- Tractor

- Kubotas: L3240GST B2320HST B5100D & G5200H

I'd reinforce the bottom corners of the square tube where the rippers bear on the tube inner wall. They will want to tear out the tube wall. Something as simple as welding a piece of 1/2 x 1" strap might buy you a lot of local shear strength. Looking good - when will you start fabrication? Don't forget to take lots of pictures!