Part of the dealer prep of my machine undoubtedly included leveling the blades. I was reading the procedure in my manual, and I see that the blades should be level from side to side +/- 1/8". And from front to back, the front should be lower than the back by no more than 1/4" and no less than 1/8". Here is my question. The salesman told me that the rear is the lowest part of the deck on these machines. He said that helps to create a partial vacuum to aid in the processing of clippings. Idk which is right. Any help?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mowing Blade leveling Zero turn

- Thread starter feetr2c

- Start date

- Views: 7556

More options

Who Replied?

/ Blade leveling Zero turn

#1

prosperity

Platinum Member

He's probably talking about the shell of the deck itself being lower in the rear. When doing the deck leveling (your figures are correct) the measurements are taken from the ends of the blades themselves.

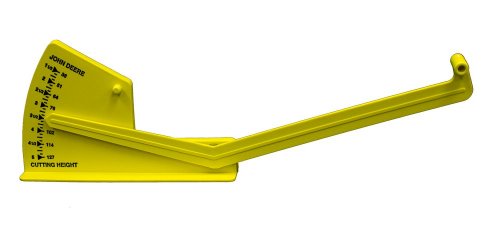

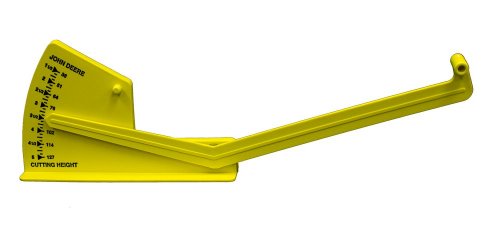

This is what is used to perform that:

Actually I am impressed that the dealer did the leveling routine - I've always had to do it myself.

This is what is used to perform that:

Actually I am impressed that the dealer did the leveling routine - I've always had to do it myself.

RG1

Platinum Member

Since I use my Z to make my living, pitch and knowing how to set it for what works best is important to me.

The best pitch will depend on what machine you run, but most JD's do their best work for cut and striping ability when the pitch is set at 1/4" with your weight on the seat., which means about 3/8" when you're not. Do the check over a dead flat surface. It doesn't have top be perfectly level, but even a small dip or hump can throw the readings and thus the setting off. If you have a 1/8" dip up at the left front of the machine, and a hump at the right rear, you are starting with the settings off by a 1/4" without having done anything to the machine yet.

I have used that gauge in the picture above for about 12 years. It is so easy to use and so handy to boot when trying to accurately measure everything.

The pitch is set on the blades themselves, with the two outer blades pointing perfectly straight front to rear. Measure at the bottom side of the cutting edge as close to the end of the blade as you can and still be on the blade.

The best pitch will depend on what machine you run, but most JD's do their best work for cut and striping ability when the pitch is set at 1/4" with your weight on the seat., which means about 3/8" when you're not. Do the check over a dead flat surface. It doesn't have top be perfectly level, but even a small dip or hump can throw the readings and thus the setting off. If you have a 1/8" dip up at the left front of the machine, and a hump at the right rear, you are starting with the settings off by a 1/4" without having done anything to the machine yet.

I have used that gauge in the picture above for about 12 years. It is so easy to use and so handy to boot when trying to accurately measure everything.

The pitch is set on the blades themselves, with the two outer blades pointing perfectly straight front to rear. Measure at the bottom side of the cutting edge as close to the end of the blade as you can and still be on the blade.

sunnyside360

Veteran Member

- Joined

- Aug 8, 2006

- Messages

- 1,561

- Location

- Central PA

- Tractor

- JD 3720, JD 4320, JD 835R, Kubota M4D-071, Kubota ZD1511

Have to agree with all the above and further emphasize the value of the blade leveling tool shown above and available at the John Deere store. I've been using the tool for a long time.

Ok so if I understand correctly, both pitch AND side to side leveling are done using the leveling tool on the two outer blades only. The front center blade is not used during the leveling process. Also, when adjusting pitch, if you do this using the two outer blades pointing both straight from front to back, then set the pitch so the front end of the blade is a bit lower than the back end of the blade. So that would mean that when you're done, the front center blade will be even lower yet, since it rides out forward of the two back blades. Right?

RG1

Platinum Member

Ok so if I understand correctly, both pitch AND side to side leveling are done using the leveling tool on the two outer blades only. The front center blade is not used during the leveling process. Also, when adjusting pitch, if you do this using the two outer blades pointing both straight from front to back, then set the pitch so the front end of the blade is a bit lower than the back end of the blade. So that would mean that when you're done, the front center blade will be even lower yet, since it rides out forward of the two back blades. Right?

Not exactly. The tool is only for measuring. You set the pitch by making adjustments to your own machine as outlined in your owners manual. All the blades are on the same plane basically since you are pitching them instead of the entire deck. The actual difference from the blade tip in the center to the ground (at the front end) when it is pointing front to rear is almost non existent from the side blades. If you pitched only the center blade and not the side blades, you'd still end up with the same exact scenario, only with less chance of catching anything out of whack. If you try to set the pitch on all three exactly the same, you'll just end up frustrating yourself over nothing. Trust me, if it mattered, I'd do it to mine. I have been setting both pitch and level for a lot of years on a lot of different machines, and have yet to have one not cut great when done. Don't worry that you'll end up with some sort of small trough at the center. You won't.

The side to side should be done first with the two outer blades pointing straight to each side, then do the pitch. The pitch on JD's works best when set to be 3/8" front to rear on the blades themselves, not the deck shell. then when your weight is on it, the pitch will be right at 1/4".

patchnball

Bronze Member

yep been trying to adjust deck on x530 using tool provided.....well....gave up and went back to measuring off blade tips......it works

prosperity

Platinum Member

yep been trying to adjust deck on x530 using tool provided.....well....gave up and went back to measuring off blade tips......it works

I guess I don't understand what you are saying - the tool shown is what is used for measuring off the blade tips.

SandburRanch

Veteran Member

- Joined

- Oct 12, 2010

- Messages

- 1,543

- Tractor

- NHtd75

I use a shop made tool I wouldn't trade for a dozen of those JD gauges. It has no numbers to remember, record or be concerned with.

patchnball

Bronze Member

yes prosperity you are correct. I tried to use "deck" gauge to level deck as instructed by JD, Only problem with that is my deck doesn't level blades doing that way. Thus I used a bolt......tool.... to level blades independent of mower deck.

RG1

Platinum Member

yes prosperity you are correct. I tried to use "deck" gauge to level deck as instructed by JD, Only problem with that is my deck doesn't level blades doing that way. Thus I used a bolt......tool.... to level blades independent of mower deck.

I am not understanding this comment at all. What do you mean by leveling the blades independent of the deck? That would be an incorrect thing to do, and would require shimming the spindle housing to actually do.

Pitching and leveling the deck is easy. IMO, a lot of folks overthink it, or realy don't understand it when they finally decide to try it.

With JD, you never check pitch or level of the deck shell. You do it by checking the blades with a tape or their handy gauge. There are easy to adjust hangers to change pitch and level. I can teach anyone to do it in less than 5 minutes in person. I have had people tell me that theirs won't work like the manual, and then when I ask them to show me how they are trying to do it, they are going about it completely wrong.

My JD manual says to do the side-to-side level first, using the bolts at the rear on the deck so that both side of the deck are set to your cutting height, say, 2.5 inches. Then adjust the front hangers so the front is pitched no more than 1/4". My question is in the manual they only show two blades. Mine has three. So when pitching, do I take the measurement from the tip of the front most blade? Or from the front of the other blades that they picture?

^^^^^DISREGARD THIS POST. STUPID MOBILE APP WONT LET ME DELETE IT^^^^^^^

^^^^^DISREGARD THIS POST. STUPID MOBILE APP WONT LET ME DELETE IT^^^^^^^

Last edited:

Not exactly. The tool is only for measuring. You set the pitch by making adjustments to your own machine as outlined in your owners manual. All the blades are on the same plane basically since you are pitching them instead of the entire deck. The actual difference from the blade tip in the center to the ground (at the front end) when it is pointing front to rear is almost non existent from the side blades. If you pitched only the center blade and not the side blades, you'd still end up with the same exact scenario, only with less chance of catching anything out of whack. If you try to set the pitch on all three exactly the same, you'll just end up frustrating yourself over nothing. Trust me, if it mattered, I'd do it to mine. I have been setting both pitch and level for a lot of years on a lot of different machines, and have yet to have one not cut great when done. Don't worry that you'll end up with some sort of small trough at the center. You won't.The side to side should be done first with the two outer blades pointing straight to each side, then do the pitch. The pitch on JD's works best when set to be 3/8" front to rear on the blades themselves, not the deck shell. then when your weight is on it, the pitch will be right at 1/4".

You are talking as if pitch is an adjustment that is made to the blades themselves. How is this possible? According to my manual, it's done by adjusting the front most hangers so the entire deck tilts forward slightly. By slightly I mean only enough so that the front of a blade is 1/4" lower that the back of the same blade.

RG1

Platinum Member

You are talking as if pitch is an adjustment that is made to the blades themselves. How is this possible? According to my manual, it's done by adjusting the front most hangers so the entire deck tilts forward slightly. By slightly I mean only enough so that the front of a blade is 1/4" lower that the back of the same blade.

No, that is exactly what I am saying, but you don't check the deck shell itself for the pitch, but rather the blades.

Ok, RG1, so I understand now. Haven't checked my machine yet, as the dealer says they did it as part of set up. I do have a JD gauge though. So if I'm understanding you correctly, the procedure would go something like this. Park on level hard surface, set deck lever to desired height. Gauge wheels should not touch the ground. Set side blades so they are pointing straight across. Set gauge under outer tip of left blade. Adjust rear hanger on that side to achieve cutting height that was selected earlier. Then adjust right hand side to same. The point side blades to point front and back. Place gauge under front tip of left blade and use FRONT hanger on that side to set 1/8" lower than previous measurement. Then so the same with right blade and you're done.

The reason I said only 1/8 inch in pitch is because doing it with only the side blades, left to right level was established with the blades pointing outward, which would be one half the diameter of the circle that a blade makes when spinning, thus the full pitch would be 1/4"

The reason I said only 1/8 inch in pitch is because doing it with only the side blades, left to right level was established with the blades pointing outward, which would be one half the diameter of the circle that a blade makes when spinning, thus the full pitch would be 1/4"

My JD manual says to do the side-to-side level first, using the bolts at the rear on the deck so that both side of the deck are set to your cutting height, say, 2.5 inches. Then adjust the front hangers so the front is pitched no more than 1/4". My question is in the manual they only show two blades. Mine has three. So when pitching, do I take the measurement from the tip of the front most blade? Or from the front of the other blades that they picture?

^^^^^DISREGARD THIS POST. STUPID MOBILE APP WONT LET ME DELETE IT^^^^^^^

I have been playing with the adjustment on my Kubota BX. I think I may have been interpreting the pitch wrong, I need to look at the manual again. On a 3 blade deck the front blade sits forward of the outer blades. So if you are supposed to have a 1/4'' of pitch I am wondering if you should check the center blade for the front and an outer blade for the rear because if you just check an outer or rear blade you could still be off some. Pitch does affect vacuum too.

chevy

Platinum Member

- Joined

- Mar 6, 2003

- Messages

- 919

- Location

- East Central, Indiana

- Tractor

- Kioti CK3510SE HST, John Deere X739

I have been playing with the adjustment on my Kubota BX. I think I may have been interpreting the pitch wrong, I need to look at the manual again. On a 3 blade deck the front blade sits forward of the outer blades. So if you are supposed to have a 1/4'' of pitch I am wondering if you should check the center blade for the front and an outer blade for the rear because if you just check an outer or rear blade you could still be off some. Pitch does affect vacuum too.

I have always set the pitch from the blade tip closest to the front of the deck to the blade tip closest to the rear of the deck.

RG1

Platinum Member

Ok, RG1, so I understand now. Haven't checked my machine yet, as the dealer says they did it as part of set up. I do have a JD gauge though. So if I'm understanding you correctly, the procedure would go something like this. Park on level hard surface, set deck lever to desired height. Gauge wheels should not touch the ground. Set side blades so they are pointing straight across. Set gauge under outer tip of left blade. Adjust rear hanger on that side to achieve cutting height that was selected earlier. Then adjust right hand side to same. The point side blades to point front and back. Place gauge under front tip of left blade and use FRONT hanger on that side to set 1/8" lower than previous measurement. Then so the same with right blade and you're done.

The reason I said only 1/8 inch in pitch is because doing it with only the side blades, left to right level was established with the blades pointing outward, which would be one half the diameter of the circle that a blade makes when spinning, thus the full pitch would be 1/4"

You could go about it like that, but I don't. I stick to the same routine no matter who made the machine, and it has never let me down, or made things harder. JD usually has them side to side pretty darn good, but the pitch can be off a lot of the time.

1- Make sure to have someone or something that approximates your weight on the seat and the tire pressures set to the PSI you will run the machine at, because your weight will affect pitch by at least 1/8", so I set mine at 3/8" without weight on the seat to end up with 1/4" with me on the seat, and that works very accurately for me.

2- I check for side to side level with the blades as you described, get them both the same if they aren't already, then-

3- point them straight front to back, set the front of the blades to match the HOC indicator since the front end is where the lowest point of the arc of cut takes place, and then set pitch and check at both the front and the rear end of the blade. Just doing the 1/8" thing should work in theory, but I don't trust anything that is theory... ever. I like to know for absolute certain what I have so that I get the best cut possible.

coachlickiss

New member

RG1 is spot on with his procedure. I was frantically reading the posts hoping to finally see mention of tire pressures! Without verifying tire pressure the tail chase is on! The gauge is cool, but setting the deck height indicator to the height you most likely want to use regularly, three (3) inches for example and cutting an accurate gauge block or four can expedite the process too. With some chain systems a deck accurately set to four inches might actually measure three and a quarter when subsequently set at three for example, so I always liked to "zero" on the setting I was typically planning to use.

Works great!! The only stupid thing I encountered was when setting the pitch. There is one center blade but the pitch is adjusted by two hangers in the front. My solution was to first level the front using two identical blocks under the gauge wheels. Then turn each of the front nuts equally to establish the proper pitch.

Here are some similar links:

- Replies

- 12

- Views

- 4K