Kubota Runs!

After some foibles about not ordering hoses and some of the gaskets, I have it back together and it runs very well. Rebuilt head, rebuilt injectors, valve job, valve clearance adjusted, new hoses, gaskets and belts. New Rotella T 15w40 (?) and new ~ 50/50 Rotella ELC/distilled water (might be closer to 60/40, have to look at that -- coolant capacity is only 2.2 quarts!). Can't tell much difference in the way it runs than before though. It always started and ran fine. Might start a little faster. Not hard to start at all. Just overheated. Before I rebuilt it, it would overheat in 10-15 minutes. Seemed like it was using water. We would always be putting distilled water in it (stealing it from under my wife's ironing board).

BUT ...

It still overheats! :banghead:

But only if you put some load on it. Just sitting there running full throttle, the temp gauge will only go to the middle white line. If you mow with it, it will creep up close to the highest white line (just before the red area). This is about where we would normally shut it down and let it cool off. We would let it get close to or almost touch the top white line.

SO ...

This is where it gets interesting, or maybe laughable for those of you who know what you're doing.

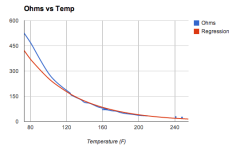

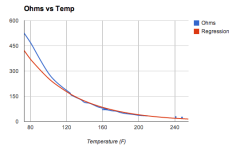

So I started wondering... Exactly how hot is it actually getting? Time to pull out some nerd power. So I did what I probably should have done in the first place -- pull off the temp sensor and check it out (screws into a water passage on the head on the opposite side of the head from the water pump). So it's just a resistor thermocouple type thing, so we got a pot of water on the stove, and a digital cooking thermometer (again stolen from the wife), and hooked the sensor up to an ohm meter. Put the thermometer and sensor the pot and turn on the heat. We took readings of temp and resistance and made a table of the findings. But we could only get to about 210 F, so we plugged in into a spreadsheet and did an exponential regression function (just finds a function that approximates your data set). This allowed us to carry the values out further and it was pretty close.

On to the mower. I wanted to know how hot it was actually getting and also what temp the sensor thought it was. We had a point and shoot infrared thermometer and also a thermocouple that comes with a nice Fluke multimeter (s'posed to be pretty accurate). So we got all set up and stuck the Fluke probe in the radiator right where the upper radiator hose will flow right onto it. We also took measurements with the infrared on the surface of the radiator right next to the upper radiator hose. We used the infrared to measure the temp of the surface of the head next to the temp sensor and also the surface of the block below the head.

Turns out that the measuring radiator surface with infrared gave very close to the same reading as the Fluke probe in the coolant flowing from the upper radiator hose (within about 2 deg or so). So we dropped the Fluke and put the radiator cap back on. The block temp by the temp sensor was also within a few degrees of the radiator by the upper hose. The temp sensor was consistently indicating a higher temp than we measured with the Fluke or the infrared. Seemed like the hotter it got, the more difference there was between the two. We did notice when the thermostat opened.

We could only get it to about the middle (straight up) white line while sitting there, so I started mowing with it -- pretty tall kinda wet grass with kinda dull blades. The temp gauge started creeping higher. I wanted to know the temp when it touched the top white line. But it never got there. It stopped going up when it was just a little bit before the upper white line -- a little over 3/4 of the way from the middle line to the top line -- bout an 1/8" from the top line. Hmmm. So we checked the temp. The radiator but the upper hose measured 209 F and the head by the temp sensor measured 206 F -- but it cools down kinda fast, so hard to know. The block was 211 F. The temp sensor resistance showed that it thought it was about 214 F. I read that many engines (and have experience with one) have a thermo switch to shut them down at 230 F.

So whaddaya think?!

- Is my temperature measuring good enough?

- Are the temps in the normal range?

- Is my temp sensor bad?

- Or is it the gauge?

- Or some of both?

I still need to do more mow testing to see if it will eventually go up higher, but it was starting to rain and I need to sharpen the blades. Maybe tomorrow.