jwmorris

Veteran Member

- Joined

- Oct 3, 2007

- Messages

- 1,135

I spliced one together with a 30' span in my shop for the same thing. I also welded plates in the flat although I doubt it needed it.

The stats for loading of beams already have a fudge factor of about 4 built in. When an engineer then adds in his own fudge factor you end up with this situation. I recall a pipe rack built on a construction site once. Most had 6" I beam verts but this one had about 10 or 12" extra heavy beams. I commented to an engineer about how this rack must be heavily loaded and he said no, just one pipe on top. I laughed and said why such massive beam weights and he said a new engineer designed it and they failed to check the design properly by a veteran engineer. It got fabricated that way so, it got installed. Not a big % of $$$ over-run on a couple hundred million dollar project, but if this had been a one of installation, it could have tripled, quadrupled or more the cost to build.No

Rather the engineer err on the "overbuilt" side of things instead of the "it's good enough" side of things.

Sent from my iPhone 5s 64Gb using TractorByNet

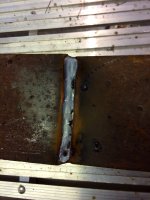

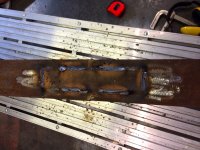

So a bit of a snag; may need to scrap project or get a matching piece. (I'm doing this for my fathers shop)

As you can see from the pics one piece is just a little taller than the other; same thicknesses.

Sent from my iPhone 5s 64Gb using TractorByNet

I just HAD to quote that on my facebook page, keeping it in style with the plastic welding is hilariousTheres all kind of engineers some so full of hot air you could poke a hole in them and do some plastic welding.

:laughing: :laughing: :laughing: Well ericher you know your 3 choices 1) give up 2) spend your time looking for more steel 3) level out the trolley track and keep moving. That little offset in the flanges will weld up nicely with filler plates

Since you posted pic's, I'll comment. For 500 lbs. it will hold. Forget excuses, that's a water blister, a minor inconvenience as far as welding goes. As far as quality it has has some rather obvious flaws. Did your experienced welding friend inspect it and what did he say? Why didn't you do a better job cleaning it up before welding? You burned hot but maybe too hot. It looks like you may have been going a little too slow for the heat and putting too much filler in one pass. Were you weaving or going in circles while welding? You left unfilled craters and undercut and worse is you left them on the edge of the beam. Great place for a crack to start. I hate to be so critical but you've got good equipment and asked for advice before proceeding, did a good job lining/clamping everything up properly and in the the end it looks like you got in a hurry and scrimped on the most important details. Shouldn't fall apart??? That's just another way of saying good enough. Sorry, I don't understand.

Arc Weld is giving feedback and will "encourage" me to do a better job next time. I realize posting pics that I would get it from someone but hey- I have thick skin and can take it.Arc your paragraph 2 is good, it's the kind of feedback members appreciate, will draw more members to post pics. I understood "shouldn't fall apart" as a joke.

I realize posting pics that I would get it from someone but hey- I have thick skin and can take it.

Posting pics should not result in 'getting it from someone' and nor should people have to 'have thick skin' and have the ability to 'take it'. TBN is about sharing experience and learning from one another. I believe everyone knows how to instruct, help others and offer constructive criticism. A good rule of thumb is 'If I wouldn't say it to someone's face, I shouldn't type it.'

Keep in mind the rest of us learn from the constructive criticism too. I don't have much to say, because I have no experience welding something like this, but I can learn just by watching and "listening".

I think most people on this forum realize that people will sometimes tackle a project that they shouldn't because of;

Lack of experience

Lack of skill

Lack of space

Lack of equipment

I had no experience welding something like this prior to a few days ago but now do!

Does it make me a pro-no

Would I have tackled this with a borderline capacity MIG-No

Would I do it again-Yes

Hey you guys watch it or I'll loadtest one of my 120v spliced I-beams from 15 years ago!

Agreed 3/8" thick flanges (and the workpiece size) is beyond "borderline" for 120v, don't have to 'go there'. But ….what if a guy did it (on your beam size) , and it passed a load test. Would it convince you that your splice with your 252 is good enough ?

Ericher69 - It will certainly hold 500 pounds, and considering all of the rust on the beam, the weld looks as good as you might expect. If it were me, I would have spent 5-10 minutes with an angle grinder and ground off the rust within 1 inch of the weld area. That would have turned what was an acceptable outcome into something that high quality. Just a suggestion.