stormpetrel

Gold Member

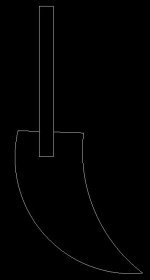

I need to weld 1/4" 316L to a 1&1/4" stainless shaft. I will be cutting out an opening in the 1/4" stainless for the stainless shaft to fit into. It's a boat rudder replacement/fix. The old 1/4" piece cracked and bent, I feel it's beyond repairing.

I just bought a Thermal Arc/Tweco Fabricator 211i. I don't want to MIG weld the stainless and buy tri-mix gas for 5 min. of welding. I din't want to scratch-start TIG weld it because I have zero TIG experience and there's still the gas issue.

I have decided to stick weld. I bought some Lincoln Excalibur 316 3/32" rods. I have only MIG welded (W/flux cored) before. Esthetics are not a big concern, as the welds will be under water.

I've run about 50 pounds of wire, and done several repairs and even fabricated stuff with success. I'm hoping that MIG welding experience will transfer to being able to learn stick welding quickly. I have ten pounds of rod, and am not afraid to burn some of it to practice. All welds will be done in the flat position.

I am looking for suggestions as to where to start amp-wise. My understanding is that stainless needs less heat. I'm also wondering how I account for the different material thickness when deciding on where to start with power.

I'm also open to any other ideas and suggestions, even though I'm positive some of them will be foolish .

.

Seriously though.....I'm looking forward to doing this project, and to getting your ideas.

I just bought a Thermal Arc/Tweco Fabricator 211i. I don't want to MIG weld the stainless and buy tri-mix gas for 5 min. of welding. I din't want to scratch-start TIG weld it because I have zero TIG experience and there's still the gas issue.

I have decided to stick weld. I bought some Lincoln Excalibur 316 3/32" rods. I have only MIG welded (W/flux cored) before. Esthetics are not a big concern, as the welds will be under water.

I've run about 50 pounds of wire, and done several repairs and even fabricated stuff with success. I'm hoping that MIG welding experience will transfer to being able to learn stick welding quickly. I have ten pounds of rod, and am not afraid to burn some of it to practice. All welds will be done in the flat position.

I am looking for suggestions as to where to start amp-wise. My understanding is that stainless needs less heat. I'm also wondering how I account for the different material thickness when deciding on where to start with power.

I'm also open to any other ideas and suggestions, even though I'm positive some of them will be foolish

Seriously though.....I'm looking forward to doing this project, and to getting your ideas.