KennyG

Elite Member

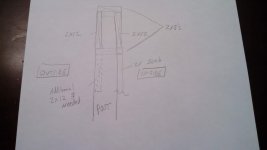

I would side with Eddie on the built up 2x12s and plywood. Make it the same thickness as the posts. I'm skeptical of wood box beams. Metal box beams work because they are one continuous material. Built up laminated timbers beams work because, even if they aren't glued (which they should be) they all act in the same loading. A wood box beam has different forces acting on the mating pieces and that would worry me. I'm not saying it's not a way to build a strong beam, I'm just saying that if I tried to structurally analyze it I would have to worry a lot about load transfer between the members.

The idea of stacking 2x12s has some merit,but I don't think you need it. 3 2x12s with plywood should be plenty to span 16 feet. If you did stack them, I would want continuous plywood sheets tying them together.

If the Amish are using boxed headers (I haven't seen this) I would guess it's to save material. Headers in house construction are often way over designed.

Anyway, these are thoughts off the top of my head without any detailed evaluation, but when we see "everyone always does it this way" there is often a reason.

The idea of stacking 2x12s has some merit,but I don't think you need it. 3 2x12s with plywood should be plenty to span 16 feet. If you did stack them, I would want continuous plywood sheets tying them together.

If the Amish are using boxed headers (I haven't seen this) I would guess it's to save material. Headers in house construction are often way over designed.

Anyway, these are thoughts off the top of my head without any detailed evaluation, but when we see "everyone always does it this way" there is often a reason.