My thinking is if the machine is stopping when the clutch is depressed then the clutch is completely disengaging

Thanks Larry,

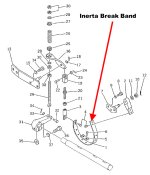

My thinking is that maybe the clutch linkage is not adjusted correctly AND the Inertia brake is not either. These two are connected on the same shaft and I am thinking that my first adjustment should be to the clutch pedal linkage and then the inertia brake. I am having the same thoughts on the steering clutches and brakes.

One thing that got me on the wrong train of thought was a technician at my local Komatsu dealer who told me that the main clutch was a dry clutch the same as the steering clutches. The main clutch was stuck when I first started working on the machine. I was able to free it by putting the machine in gear, pushing the clutch, and bumping the starter. Upon the engine cranking while in gear, with the clutch pressed, I started the engine and was able to shift gears and move the dozer for the first time in 3 yrs.

Now, I have some gear grinding issues especially when I don't get the pedal pressed all the way down while shifting. Shifting is better the longer I work the machine. So again, my thought is to adjust the clutch pedal linkage first. But, now that I realize that this is a wet clutch and that heat has an effect, is there something I should be looking at hydraulically first?

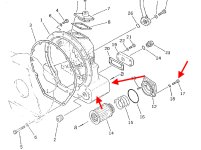

I had read on one of the forums about a screen that covers the pick-up tube for the clutch hydraulics but I don't know where the screen is located, how to access it, or if it even exists on my machine. The CD I have does not show it at all.???

I do plan to remove/rework the inertia brake band if necessary (meaning as last resort). My CD says the wear limit is 2.7mm. Just by looking at it, without measuring, it looked like it still had plenty of wear left, so I am hopeful that I can remove it, free the adjustment threads, and put it back, without pad replacement.

I want to make all the adjustments/repairs at once while I have the floorboard plate off. But, right now, I don't know exactly what I need to do, and in what order, once I get back in there. Maybe, if I get the hydraulics and linkage set properly the inertia band will be corrected as well??

I have never replaced pads on a brake before. I would like to know what kind of adhesive, pad material, and rivets I need and have those on hand before I attempt to recondition the band. Again, this would be after I remove it and confirm it is beyond it's wear limit,, and all other adjustments have been made.