woolyAcres

Platinum Member

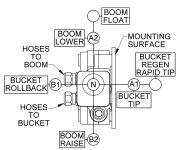

I had a chance to work on this a bit tonight. I went ahead and connected this new loader valve into the rear 3PT hydro system. This is how it was plumbed originally. The only changes now are the new hoses and loader valve. I need to raise the pressure relief valve back up to 2000psi. I had turned it way down to avoid any damage/problems while I was working with that front pump. All the functions seem to work, though it's very slow. I need to get it outside (tomorrow) where I can raise the boom all the way up and get the air out of it. When I had it dismantled I blew air through all the hard lines and the cylinders drained all over the floor so I'm sure there's still a bit of air in there.

Once I get the tractor all put back together (hood on, battery strapped down, etc) I can get it out of the garage. Maybe then I'll have some time to look at the pump I removed; however I think I'm going to try to live with what I've got for a while. If/when I return to this I'll probably be looking for a new front mounted pump where I know the requirements for it- make, model, volume, pressure, required fluid, etc. I didn't realize how important that would be.

Thanks to everyone for the input, encouragement, and education. Even if this didn't turn out the way I'd hoped, I have certainly learned a lot about my tractor and hydraulics in general.

Once I get the tractor all put back together (hood on, battery strapped down, etc) I can get it out of the garage. Maybe then I'll have some time to look at the pump I removed; however I think I'm going to try to live with what I've got for a while. If/when I return to this I'll probably be looking for a new front mounted pump where I know the requirements for it- make, model, volume, pressure, required fluid, etc. I didn't realize how important that would be.

Thanks to everyone for the input, encouragement, and education. Even if this didn't turn out the way I'd hoped, I have certainly learned a lot about my tractor and hydraulics in general.