Luke, there's a few here

http://www.tractorbynet.com/forums/welding/386590-welding-table-build-6.html

and a couple on the next page; when I get more time I might start my OWN thread instead of sidetracking another one

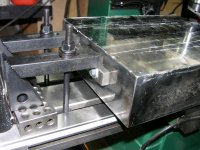

Meantime, here's a few showing the basic parts - 12" piece of 10" channel, added some pieces of FB to get more pull from the mag drill's magnets, then flattened the surface on the mill.

The vise is a Wilton reversible

Amazon.com: Wilton 145�� 45��, Reversible Mechanics Vise-Swivel Base, 5-1/2-Inch Jaw Width, 6-Inch Jaw Opening, 3-3/4-Inch Throat Depth: Home Improvement

But any normal one would work for this - my table bolts on in place of the fixed jaw. If you want accuracy it helps if you weld the jaw piece on as perpendicular to the top surface as possible, and the 1/2" thick face lets you counter bore so those screws don't interfere.

Making the table that wide lets me use vise grips and angle scraps for "stops" when I'm making multiple pieces I want all the same (pics in JeepnFord's thread)

Any other questions I'll be glad to answer, this thing just kinda "evolved" so I probably forgot to mention a few dozen OTHER things

... Steve

Here's some of the stuff I do with the "MDVT", I call 'em my "tinker toys" - all 2" receiver material, 1/4" wall - I buy the 2.53" tubing for females and standard 1/4" wall 2" tube for inserts. I probably have a few more than the pics show, whenever I can't come up with a combo of pieces that'll do what I need, out comes the saw/drill/welder :licking:

They all fit any/several of the 7 receivers I added to the FEL bucket on the old 580B, as well as any normal vehicle receiver if necessary - the receiver tube in the vise with a cutter in the hole doesn't show the OTHER end of that tube, which has a piece of scrap 1/2" FB clamped in it as a depth stop - so I can make any number of males at a time, and have ALL of them drilled in exactly the same distance from the end. This guarantees that ALL the pieces will fit ANY of the others, even if you flip one over.

The last couple pics are moving a downed tree (everything but the roots) - 2 of the 4' tubes (with 45* adapters) inboard act as "bale spears" to help lock the crown of the tree into the bucket, then the 2 6' tubes get a tow strap wrapped around the tree, which gives a "triangulation" for lift and stability. I moved that tree out of my neighbor's yard and about 100 yards down to my burn pile in one trip...