LD1

Epic Contributor

These come in handy

Baum Hydraulics Corp :: Spec Calculator

Baum Hydraulics Corp :: Spec Calculator

Oh ok, this is formula I think: Force = Initial pressure * (3.14 * diameter of cylinder^2)/4

So yes almost 11000 with 2.5", 7065 with 2"

Ok, I am back so many days without electricity. Too excusted to do anything, so many things to catch up. But I will finish that thing, it will be sooo useful. I have so much brush everywhere.

I need a little help. Can someone put a link of the pivot pin One that can take grease? I think I am slow, I cannot find it. Or else I will use just plain bolts.

These come in handy

Baum Hydraulics Corp :: Spec Calculator

The hinges of my grapple has solid pins, a washer welded on one end and other drilled for lynch pin. The tube of the hinge has a grease fitting at the middle.

My cylinders have greasable pivot pins. Not sure the source.

A lot of loaders have pins that are greasable through the pin (end has grease fitting) you may have to go to tractor dealer and look at their loaders and see if there is a pin you can adapt. This will be expense, probably cheaper to have a machine shop make you greasable pins

The hinges of my grapple has solid pins, a washer welded on one end and other drilled for lynch pin. The tube of the hinge has a grease fitting at the middle.

My cylinders have greasable pivot pins. Not sure the source.

A lot of loaders have pins that are greasable through the pin (end has grease fitting) you may have to go to tractor dealer and look at their loaders and see if there is a pin you can adapt. This will be expense, probably cheaper to have a machine shop make you greasable pins

The drive in fittings are ok until they pop out or you need to replace one, then they won't stay in as well and you end up threading the hole anyway.

For pins and bushings I buy that kind of stuff at tractor supply in the 3 point hitch/drawbar section. Between the different categories of hitches they have a decent selection from 5/8" or so through 1-1/4" diameter.

Nothing 19" long though. How about to use rod?

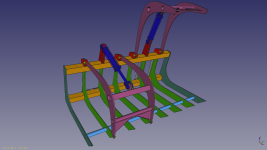

Yes, I forgot it, thank you! But vertical or horizontal? Maybe laminate them to make them thicker too?Need to gusset the lower tines

Thank you. Is something common usually on the tractor side?IMO go with SAE/ORB fittings. They seal better and are much nicer to work with especially if you have to take then apart in the future. Generally I like ORB male to JIC male 90 (or 45) degree fittings on cylinders then get female JIC hoses which come with swivels.

There is also ORFS (o-ring face seal) which is about the best for sealing and serviceability, but they aren't as common and more expensive.

Also JIC and ORB use the same thread pitch so in a pinch you can add an o-ring to a JIC male fitting and thread it into an ORB port.

I think the most common would be npt or saeYes, I forgot it, thank you! But vertical or horizontal? Maybe laminate them to make them thicker too?

Thank you. Is something common usually on the tractor side?

No, I have never seen that! Thank for the info. Maybe on the next tool, it will save me some time.Polemidis - just curious if you've browsed the patent library for ideas also?