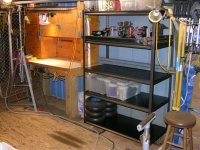

BTW, I DID get a LITTLE done on the "Crane-Tainer" (nice ring to it, huh?? :laughing: )

OP05, just noticed I didn't include that link to JeepnFord's thread - no wonder you were confused, sorry 'bout that - here 'tiz...

http://www.tractorbynet.com/forums/welding/386590-welding-table-build-6.html

All caught on the MAGnificent drill over on the jeep trail, but those holes couldn't they been done by a standard drill press, I picture a mag drill for overhead or on the wall drilling.

But now I'm a little behind the nine ball again with "Crane-Tainer"<<<"A crane is a type of machine, generally equipped with a hoist rope, wire ropes or chains, and sheaves, that can be used both to lift........... Tainer<<<<Someone who lies on the beach to get a good sun tainer...........either way you should have more done by now on in at the Crane-Tainer, after your done filling out the Hurt Feelings Report.