polemidis

Gold Member

I am looking for a cylinder for my log splitting part of my firewood processor, and I see a huge variance in prices, and some differences in rod diameters.

A few questions plz:

a)If a cylinder is rated for 3000 or 3500psi will last longer when I operate it at 2500psi, that one that is rated right at 2500psi? With the same use/abuse?

b)How important is the rod diameter other than the difference is retracting speed? I am looking ar surpluscenter, at 4" bore cylinders there are options for 1.75",2" and 2.5" rod diameters. The price range is not analog to that

c) Whats the catch with this cylinder? Its only $140 (rated at 3000psi) where the other cylinders 4" bore, cost $250-$300? Is it just an overstocked item? Maybe there is an mistake on the price?

d) I am trying to figure out if going to 4.5" bore cylinder make sense for splitting 16" of red oak, white ash, and some yellow birch and blask ash. How much slower will be the 4.5" with a 22gpm/7gpm 2-stage pump? A requirement is a 4way wedge.

e)Is there a way to restrict the movement of the rod to move only 15" than 24"? I dont see any shorter cylinders than 24" long.

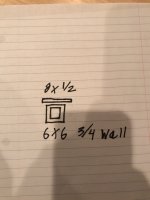

f) I-beam, "W", would the 8x28 suffice?

thank you!

A few questions plz:

a)If a cylinder is rated for 3000 or 3500psi will last longer when I operate it at 2500psi, that one that is rated right at 2500psi? With the same use/abuse?

b)How important is the rod diameter other than the difference is retracting speed? I am looking ar surpluscenter, at 4" bore cylinders there are options for 1.75",2" and 2.5" rod diameters. The price range is not analog to that

c) Whats the catch with this cylinder? Its only $140 (rated at 3000psi) where the other cylinders 4" bore, cost $250-$300? Is it just an overstocked item? Maybe there is an mistake on the price?

d) I am trying to figure out if going to 4.5" bore cylinder make sense for splitting 16" of red oak, white ash, and some yellow birch and blask ash. How much slower will be the 4.5" with a 22gpm/7gpm 2-stage pump? A requirement is a 4way wedge.

e)Is there a way to restrict the movement of the rod to move only 15" than 24"? I dont see any shorter cylinders than 24" long.

f) I-beam, "W", would the 8x28 suffice?

thank you!