You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Simple Grapple Design done!

- Thread starter polemidis

- Start date

- Views: 7362

More options

Who Replied?

/ Simple Grapple Design done!

#11

Stomper

Gold Member

Another member posted this on another thread. I am looking at building one maybe. I like the simple construction of it.

MTL 48" XL Root Grapple Hydraulic Brush Grapple Attachment - Fits all mini Bobcat skid steers — MTL Attachments

MTL 48" XL Root Grapple Hydraulic Brush Grapple Attachment - Fits all mini Bobcat skid steers — MTL Attachments

My apologies guys, I have not updated the site with the Bill of Materials and the final CAD. I got caught up with a snow plow.

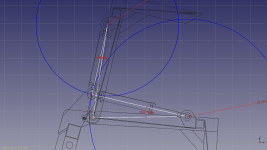

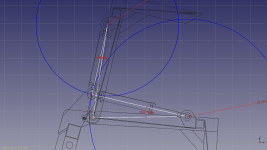

But is very close to be ready. Glyford check this picture. Is not an actual deticated stop, but its some extra insurance. The plate that protects the cylinder and offers bracing now touches the cylinder base mount at the upright position. Would you agree with that? And the angle is 3.6deg. What do you think?

Also do you think that the green pins are ok like that or should I make them longer?

But is very close to be ready. Glyford check this picture. Is not an actual deticated stop, but its some extra insurance. The plate that protects the cylinder and offers bracing now touches the cylinder base mount at the upright position. Would you agree with that? And the angle is 3.6deg. What do you think?

Also do you think that the green pins are ok like that or should I make them longer?

rScotty

Super Member

- Joined

- Apr 21, 2001

- Messages

- 9,662

- Location

- Rural mountains - Colorado

- Tractor

- Kubota M59, JD530, JD310SG. Restoring Yanmar YM165D

Also do you think that the green pins are ok like that or should I make them longer?

View attachment 535314View attachment 535313

Yes, Make them full length. Easier to fab, line up, & secure. Over-constained is also a strength advantage.

But where is the advantage in using solid pins anyway?

Instead of pins, how about using 4130 weldable tubing? 1" dia. x 1/8" wall = $15/ft. 3/16 wall = $20/ft.

Or since pins are short, with low stress, and large diam. is OK... how about black iron water pipe instead of pins?

One word: wear. Look at some of the youtube vids of people rebuilding backhoe pins, machines often have an amazing amount of wear before someone gets fed up with it enough fix it. Sometimes they won't stop using a machine until they have literally started ripping it apart (pulling the bushings out through the structure). Going with a solid pin is cheap insurance for that, as opposed to Sch40 or 1/8 wall tube.

As to letting the arm structure bump the cylinder mount, I suspect you will be okay, with one proviso...are you planning on any kind of sheet metal cover over the cylinder? Grapple means operating in brush, with sticks and branches pointing every which way. They can get into the darnedest places and damage hoses, or get into pinch points like that and stop the motion before you expect them to (while the cylinder still has leverage) and then maybe break something. So as long as you have a reasonable expectation that if someone rams a brush pile to get a bigger bite the linkage areas and hoses are mostly covered, I think you will be OK.

As to letting the arm structure bump the cylinder mount, I suspect you will be okay, with one proviso...are you planning on any kind of sheet metal cover over the cylinder? Grapple means operating in brush, with sticks and branches pointing every which way. They can get into the darnedest places and damage hoses, or get into pinch points like that and stop the motion before you expect them to (while the cylinder still has leverage) and then maybe break something. So as long as you have a reasonable expectation that if someone rams a brush pile to get a bigger bite the linkage areas and hoses are mostly covered, I think you will be OK.

jclaudii

Silver Member

- Joined

- Apr 17, 2012

- Messages

- 135

- Location

- River Valley and South Arkansas

- Tractor

- MF35, Kubota7040, Case885, Ford 1100

I'm not an expert and don't have a grapple as my caveat, but you may want to add some more flat bar for support and strength in key areas.

1st, I would like to see a center "ridge" on grapple out of flat bar. Down the spine where the cylinder is and on the front part facing down. It can be on the inside and could give things some more grip when it digs in.

2nd, lateral bracing. That seems like a long stretch between the rear of the bottom mount to the round stock that ties it in to where the teeth are. I would strongly consider adding in some slanted flat bar in direction of penetration like =o=o=\=o=o=\==- This would help prevent the tines from spreading and rock/root/stick from wedging in between the tines. It will also make it quite a bit stronger for deflection or off center approach. I would add at least one more flat bar brace on the back of the tool too.

3rd, double up on the outer most tines to make them twice as thick and the center most tine/tines. just cut out a few extra tines and weld them to each other to double your thickness of material in those locations. As I see it now it would be more likely to bend in its current state than to with the extra material on the edges and center. You would get good welds with the holes you have as well.

Think hitting a root while going forward and just skimming it on the righter outer most tine which causes the whole tractor to be deflected to the left. That is alot of weight and momentum that was absorbed by throwing the tool and the machine to the left. Or backing up and take out a small tree with the tine...done that with the bucket before. I think you have it down to where it will function as intended, now step away and think about how you could use it in a way it was not designed for or accidentally or purposely doing something that could damage it. Looks cool.

How are you doing the hydraulics?

1st, I would like to see a center "ridge" on grapple out of flat bar. Down the spine where the cylinder is and on the front part facing down. It can be on the inside and could give things some more grip when it digs in.

2nd, lateral bracing. That seems like a long stretch between the rear of the bottom mount to the round stock that ties it in to where the teeth are. I would strongly consider adding in some slanted flat bar in direction of penetration like =o=o=\=o=o=\==- This would help prevent the tines from spreading and rock/root/stick from wedging in between the tines. It will also make it quite a bit stronger for deflection or off center approach. I would add at least one more flat bar brace on the back of the tool too.

3rd, double up on the outer most tines to make them twice as thick and the center most tine/tines. just cut out a few extra tines and weld them to each other to double your thickness of material in those locations. As I see it now it would be more likely to bend in its current state than to with the extra material on the edges and center. You would get good welds with the holes you have as well.

Think hitting a root while going forward and just skimming it on the righter outer most tine which causes the whole tractor to be deflected to the left. That is alot of weight and momentum that was absorbed by throwing the tool and the machine to the left. Or backing up and take out a small tree with the tine...done that with the bucket before. I think you have it down to where it will function as intended, now step away and think about how you could use it in a way it was not designed for or accidentally or purposely doing something that could damage it. Looks cool.

How are you doing the hydraulics?

rScotty

Super Member

- Joined

- Apr 21, 2001

- Messages

- 9,662

- Location

- Rural mountains - Colorado

- Tractor

- Kubota M59, JD530, JD310SG. Restoring Yanmar YM165D

One word: wear. Look at some of the youtube vids of people rebuilding backhoe pins, machines often have an amazing amount of wear before someone gets fed up with it enough fix it. Sometimes they won't stop using a machine until they have literally started ripping it apart (pulling the bushings out through the structure). Going with a solid pin is cheap insurance for that, as opposed to Sch40 or 1/8 wall tube.

I've never designed anything specifically for deliberate abuse. But how do you figure that going to a solid pin offers more wear resistance than the thin wall bushing that it runs in? How thick should the walls of the bushing be? Which wears most? The bushing or the pin?

rScotty

I've never designed anything specifically for deliberate abuse. But how do you figure that going to a solid pin offers more wear resistance than the thin wall bushing that it runs in? How thick should the walls of the bushing be? Which wears most? The bushing or the pin?

rScotty

The reason that I went for solid pin is mostly wear, and because the outer diameter is exactly 1", with the thick pipe that serves as bushing being a few hundreds over 1" internal dimension. The flat piece that is welded at the end of the pin has a small hole for a 5/16" bolt, so be removing that bolt I can take the hole thing apart and grease it. Its not as easy to grease as a zerk, but since no water can penetrate in there I believe I will be ok to do it whenever I service the tractor.

Jclaudii, about the hydraylics, I will "T" the cylinders to work in parallel. So they can grapple to different angles if the load is uneven. They will be controlled by the 3rd function.

On the other comments give some time to think about them. Or can someone give me some numbers to add to the Finite Element MAterial Analysis? I am learning to work with that tool, but I do not know what stresses to test for

The first thing a non-greaseable pin will do is rust, jam, or gall in the hole preventing disassembly without large amounts of jacks, chains, big hammers, torches, mashed thumbs and swearing. Ask me how I know. Do not rely on any lubrication method that requires disassembly of parts to add lubrication. If anything, lube parts while in place to aid in disassembly when needed.

I don't know the metric numbers off the top of my head, but for 1/4-28 zerks, you drill in from the end 7/32, then tap 1/4-28 (fine thread). Drill crosswise through the diameter to intersect inside the mechanism, can be any size from 1/8 to 1/4". Be careful of the bit catching and breaking when it intersects the other hole. If the pin is mild steel, it is very easy to do.

I don't know the metric numbers off the top of my head, but for 1/4-28 zerks, you drill in from the end 7/32, then tap 1/4-28 (fine thread). Drill crosswise through the diameter to intersect inside the mechanism, can be any size from 1/8 to 1/4". Be careful of the bit catching and breaking when it intersects the other hole. If the pin is mild steel, it is very easy to do.