polemidis

Gold Member

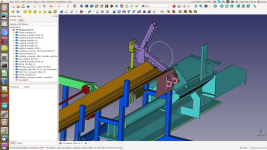

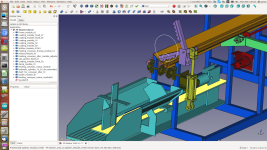

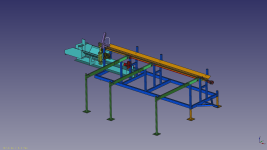

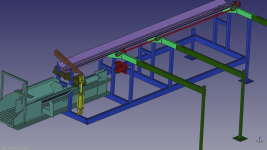

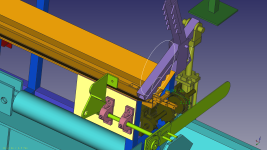

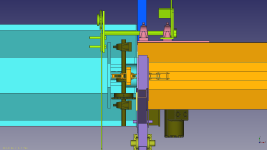

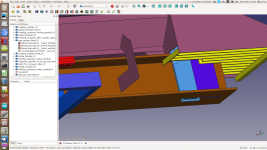

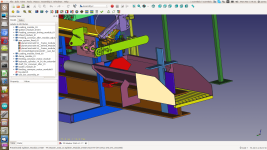

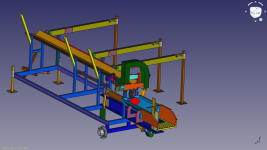

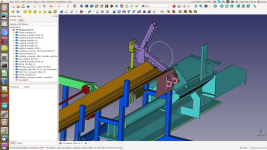

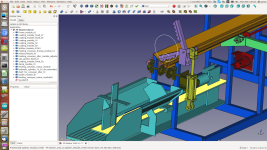

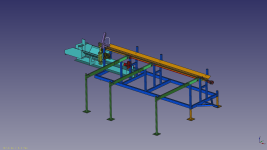

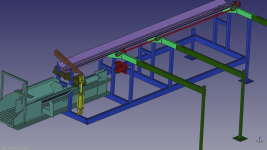

I am working on this project for a few months now, and I think its base structure is almost done. I am posting it here because I am wondering what major errors I may have before I start fabricating it.

Even though I have figured out the hydraulic saw part, I removed it for the design for now so I focus on that later on a different thread. What are your comments on the structure?

Some very obvious parts (like clamp cylinder's mount, pins, tongue etc) are missing because I am exhausted, I need to take a break

I have not done at all the conveyor part, because I got a used one on craiglist, no need to design.

The main beams are 3" x 1.5" x 1/8", most everything else is 1.5" , W-Beam is W8x35 or W8x40, the splitting cylinder will be a 5" bore.

The conveyor chains for the loading deck, and the sawing deck, will be 2060, strong but not expensive

As for now the weight of what visible is about 960lbs the center of mass is very close to the axle.

I have plenty of room for the engine(s), hydraulic tank, gas tank, etc

Tax refund money are about to come, so this and the Grapple will be fabricated soon :cool2:

I kind of bouncing in either making a smaller unit but still super efficient compared to the hand operation of firewood, or a bigger unit which wouldn't add lots to the cost. I think I balanced between these two, towards a smaller unit because of the size.

Feedback plz!

Even though I have figured out the hydraulic saw part, I removed it for the design for now so I focus on that later on a different thread. What are your comments on the structure?

Some very obvious parts (like clamp cylinder's mount, pins, tongue etc) are missing because I am exhausted, I need to take a break

I have not done at all the conveyor part, because I got a used one on craiglist, no need to design.

The main beams are 3" x 1.5" x 1/8", most everything else is 1.5" , W-Beam is W8x35 or W8x40, the splitting cylinder will be a 5" bore.

The conveyor chains for the loading deck, and the sawing deck, will be 2060, strong but not expensive

As for now the weight of what visible is about 960lbs the center of mass is very close to the axle.

I have plenty of room for the engine(s), hydraulic tank, gas tank, etc

Tax refund money are about to come, so this and the Grapple will be fabricated soon :cool2:

I kind of bouncing in either making a smaller unit but still super efficient compared to the hand operation of firewood, or a bigger unit which wouldn't add lots to the cost. I think I balanced between these two, towards a smaller unit because of the size.

Feedback plz!