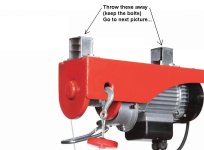

Those firewood bundles around 100 lb+-, so as of now 200lb is the most I'll be lifting and besides that, that beam is only made of hardwood glued and screwed. Those HF hoist are a decent buy but they look like they weigh as much as they lift and like you was saying hooking it to a trolley wont be easy, I'll have to do some research on that.

Ok first picture, I forgot why is to be as on, like what would exhibit A be on the need for an electric winch on a FEL? Keep in mind FEL

Second picture, or first container picture shows some nice long distant scenery where is I dont even have 300' around my house, I have to go up down the road about a mile before I can see any long distances. Looks like at your place you could take your 1874 Sharps rifle and do some long distance target practicing atleast that's what I would do if I had nice scenery like that, but not towards the west we dont want to start a war with North Korea just because someone wants to grow some much needed medical marijuana.

And in on that second first container picture, do I see in on the furthermore lot way in the back that some logging was done?

Ok first picture, I forgot why is to be as on, like what would exhibit A be on the need for an electric winch on a FEL? Keep in mind FEL

Second picture, or first container picture shows some nice long distant scenery where is I dont even have 300' around my house, I have to go up down the road about a mile before I can see any long distances. Looks like at your place you could take your 1874 Sharps rifle and do some long distance target practicing atleast that's what I would do if I had nice scenery like that, but not towards the west we dont want to start a war with North Korea just because someone wants to grow some much needed medical marijuana.

And in on that second first container picture, do I see in on the furthermore lot way in the back that some logging was done?